Haha it’s inevitable. If I get this design working I’ll post a lackaday article or something and make sure to clean up first.

Here’s the JSON! It won’t let me upload so here’s the raw text:

{

“can.config.baud_rate”: 250000,

“can.config.data_baud_rate”: 10000000,

“can.config.tx_brs”: 0,

“can.config.protocol”: 0,

“config.enable_uart_a”: false,

“config.uart_a_baudrate”: 115200,

“config.usb_cdc_protocol”: 3,

“config.uart0_protocol”: 3,

“config.max_regen_current”: 0.0,

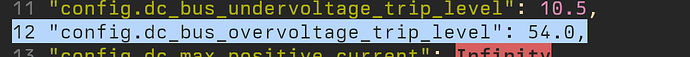

“config.dc_bus_undervoltage_trip_level”: 10.5,

“config.dc_bus_overvoltage_trip_level”: 54.0,

“config.dc_max_positive_current”: Infinity,

“config.dc_max_negative_current”: -Infinity,

“config.user_config_0”: 0,

“config.user_config_1”: 0,

“config.user_config_2”: 0,

“config.user_config_3”: 0,

“config.user_config_4”: 0,

“config.user_config_5”: 0,

“config.user_config_6”: 0,

“config.user_config_7”: 0,

“config.gpio0_mode”: 17,

“config.gpio1_mode”: 17,

“config.gpio2_mode”: 17,

“config.gpio3_mode”: 17,

“config.gpio4_mode”: 17,

“config.gpio5_mode”: 17,

“config.gpio6_mode”: 17,

“config.gpio7_mode”: 17,

“config.gpio8_mode”: 17,

“config.gpio9_mode”: 17,

“config.gpio10_mode”: 17,

“config.gpio11_mode”: 17,

“config.gpio12_mode”: 17,

“config.gpio8_pwm_mapping.endpoint”: null,

“config.gpio8_pwm_mapping.min”: 0.0,

“config.gpio8_pwm_mapping.max”: 0.0,

“config.gpio1_analog_mapping.endpoint”: null,

“config.gpio1_analog_mapping.min”: 0.0,

“config.gpio1_analog_mapping.max”: 0.0,

“config.gpio11_analog_mapping.endpoint”: null,

“config.gpio11_analog_mapping.min”: 0.0,

“config.gpio11_analog_mapping.max”: 0.0,

“config.brake_resistor0.enable”: true,

“config.brake_resistor0.resistance”: 2.0,

“config.brake_resistor0.enable_dc_bus_voltage_feedback”: false,

“config.brake_resistor0.dc_bus_voltage_feedback_ramp_start”: 51.0,

“config.brake_resistor0.dc_bus_voltage_feedback_ramp_end”: 53.0,

“config.inverter0.current_soft_max”: 80.0,

“config.inverter0.current_hard_max”: 96.0,

“config.inverter0.temp_limit_lower”: 83.95999908447266,

“config.inverter0.temp_limit_upper”: 103.11000061035156,

“config.inverter0.mod_magn_max”: 0.6781481504440308,

“config.inverter0.shunt_conductance”: 1999.9998779296875,

“config.inverter0.drv_config”: 9029553697166464,

“axis0.config.startup_max_wait_for_ready”: 3.0,

“axis0.config.startup_motor_calibration”: false,

“axis0.config.startup_encoder_index_search”: false,

“axis0.config.startup_encoder_offset_calibration”: false,

“axis0.config.startup_closed_loop_control”: false,

“axis0.config.startup_homing”: false,

“axis0.config.init_torque”: 0.0,

“axis0.config.init_vel”: 0.0,

“axis0.config.init_pos”: NaN,

“axis0.config.enable_step_dir”: false,

“axis0.config.step_dir_always_on”: false,

“axis0.config.calib_range”: 0.019999999552965164,

“axis0.config.calib_scan_distance”: 8.0,

“axis0.config.calib_scan_vel”: 2.0,

“axis0.config.index_search_at_target_vel_only”: false,

“axis0.config.watchdog_timeout”: 0.0,

“axis0.config.enable_watchdog”: false,

“axis0.config.step_gpio_pin”: 8,

“axis0.config.dir_gpio_pin”: 5,

“axis0.config.error_gpio_pin”: 6,

“axis0.config.enable_error_gpio”: false,

“axis0.config.calibration_lockin.current”: 10.0,

“axis0.config.calibration_lockin.ramp_time”: 0.4000000059604645,

“axis0.config.calibration_lockin.ramp_distance”: 0.5,

“axis0.config.calibration_lockin.accel”: 3.183098793029785,

“axis0.config.calibration_lockin.vel”: 6.36619758605957,

“axis0.config.sensorless_ramp.initial_pos”: 0.0,

“axis0.config.sensorless_ramp.current”: 10.0,

“axis0.config.sensorless_ramp.ramp_time”: 0.4000000059604645,

“axis0.config.sensorless_ramp.ramp_distance”: 0.5,

“axis0.config.sensorless_ramp.accel”: 31.83098793029785,

“axis0.config.sensorless_ramp.vel”: 63.6619758605957,

“axis0.config.sensorless_ramp.finish_distance”: 15.915493965148926,

“axis0.config.sensorless_ramp.finish_on_vel”: true,

“axis0.config.sensorless_ramp.finish_on_distance”: false,

“axis0.config.general_lockin.initial_pos”: 0.0,

“axis0.config.general_lockin.current”: 10.0,

“axis0.config.general_lockin.ramp_time”: 0.4000000059604645,

“axis0.config.general_lockin.ramp_distance”: 3.1415927410125732,

“axis0.config.general_lockin.accel”: 20.0,

“axis0.config.general_lockin.vel”: 40.0,

“axis0.config.general_lockin.finish_distance”: 100.0,

“axis0.config.general_lockin.finish_on_vel”: false,

“axis0.config.general_lockin.finish_on_distance”: false,

“axis0.config.can.node_id”: 63,

“axis0.config.can.version_msg_rate_ms”: 0,

“axis0.config.can.heartbeat_msg_rate_ms”: 100,

“axis0.config.can.encoder_msg_rate_ms”: 10,

“axis0.config.can.iq_msg_rate_ms”: 0,

“axis0.config.can.error_msg_rate_ms”: 0,

“axis0.config.can.temperature_msg_rate_ms”: 0,

“axis0.config.can.bus_voltage_msg_rate_ms”: 0,

“axis0.config.can.torques_msg_rate_ms”: 0,

“axis0.config.can.powers_msg_rate_ms”: 0,

“axis0.config.can.input_vel_scale”: 1000,

“axis0.config.can.input_torque_scale”: 1000,

“axis0.config.load_encoder”: 13,

“axis0.config.commutation_encoder”: 13,

“axis0.config.encoder_bandwidth”: 1000.0,

“axis0.config.commutation_encoder_bandwidth”: NaN,

“axis0.config.I_bus_hard_min”: -Infinity,

“axis0.config.I_bus_hard_max”: Infinity,

“axis0.config.I_bus_soft_min”: -Infinity,

“axis0.config.I_bus_soft_max”: Infinity,

“axis0.config.P_bus_soft_min”: -Infinity,

“axis0.config.P_bus_soft_max”: Infinity,

“axis0.config.torque_soft_min”: -Infinity,

“axis0.config.torque_soft_max”: Infinity,

“axis0.config.motor.motor_type”: 0,

“axis0.config.motor.pole_pairs”: 20,

“axis0.config.motor.phase_resistance”: 0.03200148791074753,

“axis0.config.motor.phase_inductance”: 1.4335515515995212e-05,

“axis0.config.motor.phase_resistance_valid”: true,

“axis0.config.motor.phase_inductance_valid”: true,

“axis0.config.motor.torque_constant”: 0.08269999921321869,

“axis0.config.motor.direction”: -1.0,

“axis0.config.motor.current_control_bandwidth”: 1000.0,

“axis0.config.motor.wL_FF_enable”: false,

“axis0.config.motor.bEMF_FF_enable”: false,

“axis0.config.motor.ff_pm_flux_linkage”: 0.0,

“axis0.config.motor.ff_pm_flux_linkage_valid”: false,

“axis0.config.motor.motor_model_l_d”: 0.0,

“axis0.config.motor.motor_model_l_q”: 0.0,

“axis0.config.motor.motor_model_l_dq_valid”: false,

“axis0.config.motor.calibration_current”: 10.0,

“axis0.config.motor.resistance_calib_max_voltage”: 2.0,

“axis0.config.motor.current_soft_max”: 50.0,

“axis0.config.motor.current_hard_max”: 70.0,

“axis0.config.motor.current_slew_rate_limit”: 10000.0,

“axis0.config.motor.fw_enable”: false,

“axis0.config.motor.fw_mod_setpoint”: 0.6103333234786987,

“axis0.config.motor.fw_fb_bandwidth”: 500.0,

“axis0.config.motor.acim_gain_min_flux”: 10.0,

“axis0.config.motor.acim_autoflux_enable”: false,

“axis0.config.motor.acim_autoflux_min_Id”: 10.0,

“axis0.config.motor.acim_autoflux_attack_gain”: 10.0,

“axis0.config.motor.acim_autoflux_decay_gain”: 1.0,

“axis0.config.motor.acim_nominal_slip_vel”: 2.3399999141693115,

“axis0.config.motor.sensorless_observer_gain”: 1000.0,

“axis0.config.motor.sensorless_pll_bandwidth”: 1000.0,

“axis0.config.motor.sensorless_pm_flux_linkage”: 0.0,

“axis0.config.motor.sensorless_pm_flux_linkage_valid”: false,

“axis0.config.motor.power_torque_report_filter_bandwidth”: 8000.0,

“axis0.config.anticogging.enabled”: false,

“axis0.config.anticogging.max_torque”: 0.15000000596046448,

“axis0.config.anticogging.calib_start_vel”: 1.0,

“axis0.config.anticogging.calib_end_vel”: 0.15000000596046448,

“axis0.config.anticogging.calib_coarse_tuning_duration”: 60.0,

“axis0.config.anticogging.calib_fine_tuning_duration”: 120.0,

“axis0.config.anticogging.calib_fine_dist_scale”: 1.0,

“axis0.config.anticogging.calib_coarse_integrator_gain”: 10.0,

“axis0.config.anticogging.calib_bidirectional”: true,

“axis0.motor.motor_thermistor.config.gpio_pin”: 4,

“axis0.motor.motor_thermistor.config.r_ref”: 10000.0,

“axis0.motor.motor_thermistor.config.t_ref”: 25.0,

“axis0.motor.motor_thermistor.config.beta”: 3435.0,

“axis0.motor.motor_thermistor.config.temp_limit_lower”: 110.0,

“axis0.motor.motor_thermistor.config.temp_limit_upper”: 130.0,

“axis0.motor.motor_thermistor.config.enabled”: true,

“axis0.controller.config.enable_vel_limit”: true,

“axis0.controller.config.enable_torque_mode_vel_limit”: true,

“axis0.controller.config.enable_gain_scheduling”: false,

“axis0.controller.config.gain_scheduling_width”: 0.0010000000474974513,

“axis0.controller.config.enable_overspeed_error”: true,

“axis0.controller.config.control_mode”: 2,

“axis0.controller.config.input_mode”: 2,

“axis0.controller.config.pos_gain”: 20.0,

“axis0.controller.config.vel_gain”: 0.1666666716337204,

“axis0.controller.config.vel_integrator_gain”: 0.3333333432674408,

“axis0.controller.config.vel_integrator_limit”: Infinity,

“axis0.controller.config.vel_limit”: 10.0,

“axis0.controller.config.vel_limit_tolerance”: 1.2000000476837158,

“axis0.controller.config.vel_ramp_rate”: 10.0,

“axis0.controller.config.torque_ramp_rate”: 0.009999999776482582,

“axis0.controller.config.circular_setpoints”: false,

“axis0.controller.config.circular_setpoint_range”: 1.0,

“axis0.controller.config.absolute_setpoints”: false,

“axis0.controller.config.use_commutation_vel”: false,

“axis0.controller.config.use_load_encoder_for_commutation_vel”: false,

“axis0.controller.config.commutation_vel_scale”: 1.0,

“axis0.controller.config.steps_per_circular_range”: 1024,

“axis0.controller.config.homing_speed”: 0.25,

“axis0.controller.config.inertia”: 0.0,

“axis0.controller.config.input_filter_bandwidth”: 20.0,

“axis0.controller.config.spinout_mechanical_power_bandwidth”: 20.0,

“axis0.controller.config.spinout_electrical_power_bandwidth”: 20.0,

“axis0.controller.config.spinout_mechanical_power_threshold”: -10.0,

“axis0.controller.config.spinout_electrical_power_threshold”: 10.0,

“axis0.trap_traj.config.vel_limit”: 2.0,

“axis0.trap_traj.config.accel_limit”: 10.0,

“axis0.trap_traj.config.decel_limit”: 0.5,

“axis0.min_endstop.config.gpio_num”: 0,

“axis0.min_endstop.config.enabled”: false,

“axis0.min_endstop.config.offset”: 0.0,

“axis0.min_endstop.config.is_active_high”: false,

“axis0.min_endstop.config.debounce_ms”: 50,

“axis0.max_endstop.config.gpio_num”: 0,

“axis0.max_endstop.config.enabled”: false,

“axis0.max_endstop.config.offset”: 0.0,

“axis0.max_endstop.config.is_active_high”: false,

“axis0.max_endstop.config.debounce_ms”: 50,

“axis0.enable_pin.config.gpio_num”: 7,

“axis0.enable_pin.config.enabled”: false,

“axis0.enable_pin.config.offset”: 0.0,

“axis0.enable_pin.config.is_active_high”: false,

“axis0.enable_pin.config.debounce_ms”: 50,

“axis0.mechanical_brake.config.gpio_num”: 0,

“axis0.mechanical_brake.config.is_active_low”: true,

“axis0.pos_vel_mapper.config.circular”: false,

“axis0.pos_vel_mapper.config.circular_output_range”: 1.0,

“axis0.pos_vel_mapper.config.scale”: 1.0,

“axis0.pos_vel_mapper.config.offset_valid”: false,

“axis0.pos_vel_mapper.config.offset”: 0.0,

“axis0.pos_vel_mapper.config.approx_init_pos_valid”: false,

“axis0.pos_vel_mapper.config.approx_init_pos”: 0.0,

“axis0.pos_vel_mapper.config.index_offset_valid”: false,

“axis0.pos_vel_mapper.config.index_offset”: 0.0,

“axis0.pos_vel_mapper.config.use_index_gpio”: false,

“axis0.pos_vel_mapper.config.passive_index_search”: false,

“axis0.pos_vel_mapper.config.index_gpio”: 10,

“axis0.pos_vel_mapper.config.use_endstop”: false,

“axis0.commutation_mapper.config.circular”: true,

“axis0.commutation_mapper.config.circular_output_range”: 1.0,

“axis0.commutation_mapper.config.scale”: -20.0,

“axis0.commutation_mapper.config.offset_valid”: true,

“axis0.commutation_mapper.config.offset”: -5.460582733154297,

“axis0.commutation_mapper.config.approx_init_pos_valid”: false,

“axis0.commutation_mapper.config.approx_init_pos”: 0.0,

“axis0.commutation_mapper.config.index_offset_valid”: false,

“axis0.commutation_mapper.config.index_offset”: 0.0,

“axis0.commutation_mapper.config.use_index_gpio”: false,

“axis0.commutation_mapper.config.passive_index_search”: false,

“axis0.commutation_mapper.config.index_gpio”: 10,

“axis0.commutation_mapper.config.use_endstop”: false,

“axis0.interpolator.config.dynamic”: true,

“rs485_encoder_group0.config.mode”: 0,

“rs485_encoder_group1.config.mode”: 0,

“inc_encoder0.config.enabled”: false,

“inc_encoder0.config.cpr”: 8192,

“hall_encoder0.config.enabled”: false,

“hall_encoder0.config.hall_polarity”: 0,

“hall_encoder0.config.hall_polarity_calibrated”: false,

“hall_encoder0.config.ignore_illegal_hall_state”: false,

“hall_encoder0.config.edges_calibrated”: false,

“hall_encoder0.config.edge0”: NaN,

“hall_encoder0.config.edge1”: NaN,

“hall_encoder0.config.edge2”: NaN,

“hall_encoder0.config.edge3”: NaN,

“hall_encoder0.config.edge4”: NaN,

“hall_encoder0.config.edge5”: NaN,

“spi_encoder0.config.ncs_gpio”: 12,

“spi_encoder0.config.mode”: 0,

“spi_encoder0.config.delay”: 0.0,

“spi_encoder0.config.max_error_rate”: 0.004999999888241291,

“spi_encoder0.config.baudrate”: 1687500,

“spi_encoder0.config.biss_c_bits”: 18,

“spi_encoder1.config.ncs_gpio”: 12,

“spi_encoder1.config.mode”: 0,

“spi_encoder1.config.delay”: 0.0,

“spi_encoder1.config.max_error_rate”: 0.004999999888241291,

“spi_encoder1.config.baudrate”: 1687500,

“spi_encoder1.config.biss_c_bits”: 18

}