I have a BLDC spindle motor for my CNC that I want to control with an ODrive. Having the ability to precisely control the spindle speed and get realtime feed back on things like current makes it ideal. I need to run the wires through two 1 meter drag chains and still have some extra to get into the electronics enclosure where the ODrive will live. I am planning on using 12 gauge wire for this. Is this wire length going to be a problem? Should I go with 10 gauge wire instead?

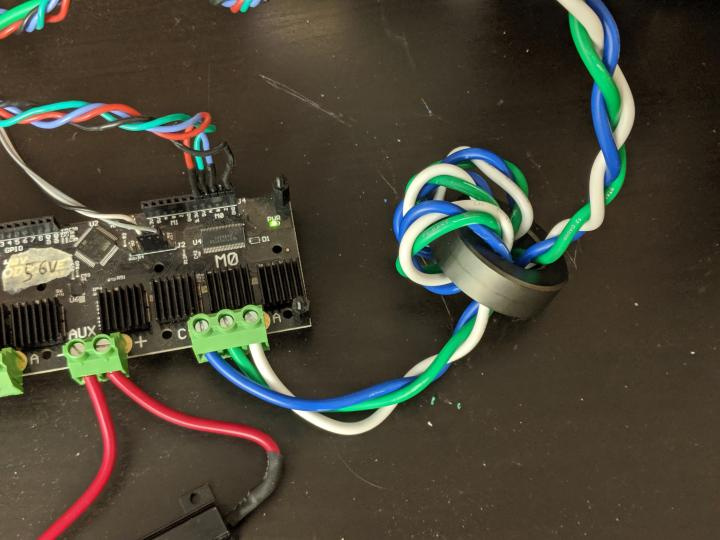

Depends on your duty cycle and phase current requirements. Braid your wires and wrap them around a toroid core a few times to dramatically reduce noise. Make sure all three wires go through together!

Also, use a differential encoder if you can, and use shielded twisted pair.

1 Like

As it is a spindle I wasn’t planning on using an encoder. I need velocity control, not position. It does have hall effect sensors though which I’ll run through shielded wire.

I have a 24V 350W power supply for it currently. I may upgrade to a 500W power supply at some point.