Hi, I’m very new to odrive, I am working on a project using Odrive Micro to control a CubeMars R60 115kv direct drive motor with a AMT10E2 encoder. The controller calibrates and I can tune the motor to a stable operation but in position hold mode, when I tune the motor, the max holding torque seems very low drawing just 0.75amps at 24v, I have tried different motors and get the same results. What am I doing wrong or is this the max torque I can expect?

Hi, and welcome!

When you say “0.75A”, where/how are you specifically measuring this? Note that the ODrive actually puts out more current to the motor than it draws from the power supply (in nearly all cases), so it’s important to look at the ODrive’s self-reported motor current numbers (e.g. the “current” graph in the GUI dashboard, or the iq_measured property in the inspector tab), as opposed to the supply current numbers (e.g. the digital readoutput on a bench power supply, or the ibus property in the inspector tab).

The Micro can do about 7A peak / 3.5A ish continuous, and the R60 has a torque constant of 0.075 Nm/A. So if you set the current limit to about 3.5A then you should expect about 3.5*0.075 = 0.26 Nm. From the drawing, the motor is about 34.5mm in diameter, so that’s 0.26 Nm / 34.5mm = 7.5N = 1.7 pound-force (or 0.78 kg-force, if you’re in a country with sane units). So I definitely would expect it to be easily movable by hand – you’d likely want some sort of gear or belt reduction if you want more torque out of this motor.

That being said, this motor looks like it has a max continuous current of about 7.6A and a peak current of 23.2A – that’s both higher than the Micro can do. Might be worth considering using an S1 for this – alternatively, there are some Cubemars motors that are a better match for the Micro’s capabilities, I personally like the the GL80 KV30, which can do about 1Nm continuous / 2Nm peak with a Micro.

All that being said, always happy to help find a motor that best meets your application and requirements! If you’re able to give some details as to the actual torque and speed you require, I’ll see if a motor comes to mind!

Thank you, this is a lot of help and makes a lot of sense!

I would love some recommendations on motor candidates for my project and can now see that 115kv is not adequate for the torque density that I’m looking for.

My project requires a maximum of 400rpm and ideally up to 5nm of holding torque and upgrading to the S1 is fine for this project.

Other considerations is high resolution rotary encoder (currently using the CUI AMT10E2-V) as my project is focused on torque measurement for machine learning. The second requirement is that I need a duel shaft motor as I have loads on both sides.

Motor suggestion would be greatly appreciated, currently direct drive is my prioritie as torque measurement resolution is paramount.

Really appreciate your help.

Regards

Luuk

Super appreciate the clear requirements!

Okay, 400RPM @ 5Nm is about 210W, which is higher than the Micro’s max of about 180W peak at 24V, so you definitely want an ODrive S1.

5Nm direct drive holding torque is a bit high, but totally doable.

Quick note:

can now see that 115kv is not adequate for the torque density that I’m looking for.

Would recommend giving this a quick read Things in Motion: Understanding BLDC electric motor constants - The Kv torque fallacy

Quick tl;dr:

- 5Nm is a good amount of torque, it’s going to take a large/expensive/high current motor to do that directly (see 3, 4, 5, 6, 7 below), and only one or two out there will meet the dual shaft requirement (6)

- There are good options that almost meet your torque/speed needs (see 1, 2)

- I think you’ll end up having to do a small/transparent reduction (see 1, as well as diagram below)

Some thoughts:

- If you can handle a QDD motor (quasi direct drive, basically motor + small, high torque transparency gearbox designed for proprioception) you could use the AKE60-8 at 48V. You’d get up to about 375 RPM at no-load, and 280 RPM at 5Nm load, but the output is only on one side

- GL100 can do 3Nm continuous / 7.7Nm peak, but you’d have to add a press-fit or red loctite glue’d shaft, and it can only do 350RPM no-load @ 48V / 200 RPM at 3Nm load, probably not the best fit for your application.

- ATO-110BLD1900 and ATO-D110BLD1500 can do 6Nm and 4.78Nm continuous respectively, at more than enough speed, but shaft only on one side (and expensive!)

- S1+M8325s can do 5Nm continuous (at plenty of RPM) if you can get some air blowing through the motor. It would require 60A from the S1, so you’d need a 24V supply (see current-voltage derating curve here), and you’d have to mount the S1 elsewhere, ideally with a heatsink, which would need an OA1 or similar for the motor position sensing. And it’s tricky to mount a shaft to the M8325s due to the face/flange mount, and you still have the issues with the shaft only on one side.

- T-Motor U13II (no issues with your torque/speed, but expensive and face mount only, like the M8325s)

- I think this is the best solution if you really need a dual shaft. Use a Flipsky 80100 – it’s dual shaft, and should be able to do about 80A continuous for your 5Nm requirement. That being said, that’s a shitton of current (to use the technical term), which you would likely need the ODrive Pro for.

- If you have access to a machine shop, and want to do some learning, the best solution here is to use a frameless torque motor, like the Cubemars RO100. It’ll do 4Nm continuous (I’m sure it’s fine to stretch to 5Nm), and plenty of RPM, but note that this is literally just the motor stator and rotor – you have to design a housing with bearings and the like – sort of like a DIY motor kit, haha. Good option if you have access to some savvy mechanical engineers.

- Last option, as a janky solution you could use a hub motor, and figure out your shaft mounting solution. Something like this. They say 6Nm continuous torque and 300RPM at 24V – that’ll be 600RPM at 48V, so that would totally work for your application. The main issue is that I have no clue how you’d go about mounting an output shaft to this, haha.

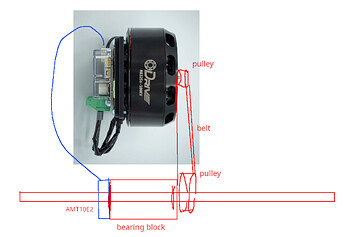

Lots of text, apologies. To sum it up, I think 5Nm continuous, especially from an S1, is going to be quite tricky. The good news is that 200W is quite low power, all things considered. I think you could move this from “tricky” to “trivial” with a simple design change to add a belt reduction; e.g. a S1+M8325s kit plus a 2:1 belt reduction would get you an easy/comfortable 6.6Nm holding torque at up to ~800 RPM at 24V. And you could use an AMT10E2 for the output shaft, getting super nice high resolution torque and pos/vel control/sensing. Something like this (apologies for the shitty diagram):

Or kind of like this video: https://www.youtube.com/shorts/iS514g3hL9Q

Of course, this would be pretty big, and it’s a lot more speed than you need, but smaller motors will need a larger reduction. If you can make that AKE60-8 work for your application, I think that’s maybe what I’d consider pursuing, since it’s designed for torque transparency.

Oh! @Luuk_Veltkamp I totally forgot about Steadywin.

This is another one of those torque transparency-optimized QDD motors, the 6010-8 will do 5Nm continuous at about 200 RPM (at 48V),

And they have the GIM8108-6, which will do 5.5Nm continuous at 600 RPM (get the 24V version but run it at 48V):

That’ll be a bit harder to source/buy, and you’ll have to either get it without their garbage built-in motor driver or just rip it off and toss it in the trash (then fit an OA1 or S1 on the back), but they’re good motors and very well optimized for robotics applications.

I think you could buy one here: Gim8108 Mit Mini Cheetah Exoskeleton Quadruped Four-legged Robot Dog High Torque Low Speed 24v Dc Brushless Reducer Gear Motor - Buy 24 Geared Motor 12v Dc Worm Gear Motor smart Robot Servo Motor Transaxle 24v Product on Alibaba.com

Make sure to specifically ask for the GIM8108-6 for 24V, without driver

But also once again, if you really need direct drive with dual shaft, the best way to go seems to be Flipsky 80100 + ODrive Pro. You could do it with an S1, but the S1 can do 80A max (theoretically continuous if you cool it well, but it’ll refuse to output current setpoints higher than that) which is 5.08Nm, and you probably need some torque headroom.

Come to think of it, you could get the 80100 customized for a lower KV (since you don’t need a high top speed, but a higher torque per amp means easier driving with an S1), either directly from Flipsky or with an equivalent model from FreeRCHobby (it’s a semi-common motor size). Any KV in the 30-70 RPM/V range should work, as that allows for 5Nm at < 40A from the S1 (e.g. comfortable continuous current region) while >400RPM under load at 24V (or higher). They’ll probably charge you a couple bucks for the sample, and it’ll take a few extra weeks of lead time, but that would be a great solution for this project.

Thank you very much for the time you have taken to answer my question, it has given me a lot to think about.

I am leaning towards a belt reduction option which will simplify motor selection but might also yield some other advantages for my application.

If use the odrive built in encoder on the motor side and use the AMT10e-v on the shaft side, I would have more data to work with to calculate shaft torque by comparing the 2 in real time.

Given my primary goal is to map torque on the output shaft as accurately as possible, I think this would be a good solution and can still make use of the micro.

My main concern here is that 5Nm @ 400RPM is 210W, which is more than the Micro’s max peak output power at 24V (7A * 24V = 168W) – and note continuous output is around 80-100W.

Having the encoder on the output shaft is really great, it’s also not going to help too much with torque estimation unless you can really accurately characterize the belt deflection under load.

My recommendation would be to use an S1 with a low cogging torque motor, with as small of a belt reduction as you can get. You should be able to get pretty darn good torque estimation, and if you need more then you can consider adding a torque transducer between the motor output and the belt pulley, or using a spring between the motor and belt pulley and comparing the motor output position and AMT10E2 position to calculate the torque – this is what’s done in a lot of higher end robotics (called a series elastic actuator).

I think if you can fit the S1+M8325s + a 2:1 belt reduction, that’s likely the best option here from a price and ease perspective.