Hi,

I’m aware it’s been noted that hobby motors suffer from it more, but is it possible to 100% eliminate cogging at very slow speeds?

Because no matter how much reduction you use or how fast you run a motion system, there can always be a trajectory that would require one of the motors to rotate extremely slow and steadily (ie a very shallow angle relative to one of the axes).

So even the slightest cogging should yield artifacts in these instances. I’m curious how the various CNC / 3D printer projects are handling this.

Thanks!

So far all I’ve seen is ruduction of speed via 2-1 ratio.

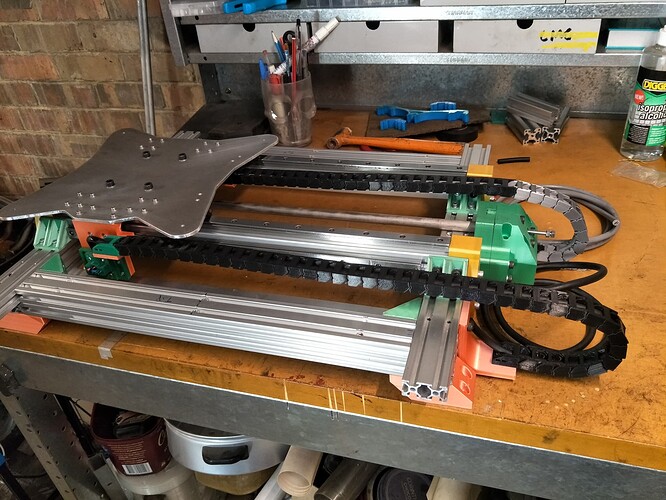

I’ve spent 12 months building a system that shouldn’t be effected by cogging .

I’m hopping to be testing it in 1-2weeks.

It’s built.

Just have work out how to configure in odrive.

How do you know it won’t be effected by cogging?

(I hope you’re right!)

Cogging is the effect of iron pulling to the magnet.

This has no iron.

I’ve built a ironless tubular linear bldc motor.

It’s not knew and it’s not ground breaking.

But more of an investigation into the topic.

Plus I can’t afford to buy one.

So I built one.

I see!

Given that you went to that much trouble would you say that the various CNC’s / printers using regular BLDC motors do in fact suffer from cogging issues then?

Yes.

That’s why I did it.

I’ve 3d printed the motor and wound the coils.

Making it into a kit any one can retro fit into there printer or cnc.

I’ve also come up with a traditional motor based on a knew motor that’s yet to come on the market.

But no time spent on it yet.

There is anticogging in the firmware that works quite well.

But it apparently still has problems at low speeds.

I am yet to even use the odrive yet.

But after seeing some of the results I thought I would give this crack and see what happens.

The big boys use skewed rotor or skewed stator motors with little to no cogging

The new odrive is a better anticogging.

Is this correct

Do you refer to professional brushless servo systems?

I’m a electric motor rewinder and repairer.

Which is why built my machine.

I’ve only seen skewed slotts on induction motors and generators.

It’s not the norm for servos.

I repair those

Looks awesome mate. Great choice of ice cream too

1 Like