Hello everyone!

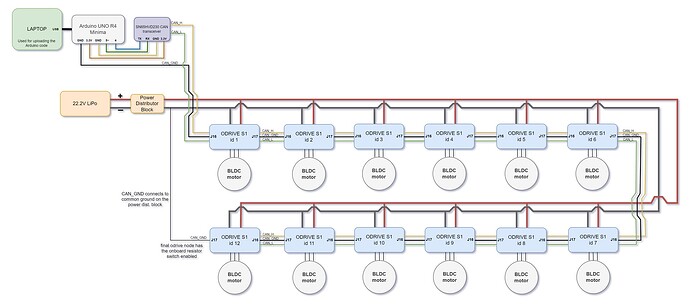

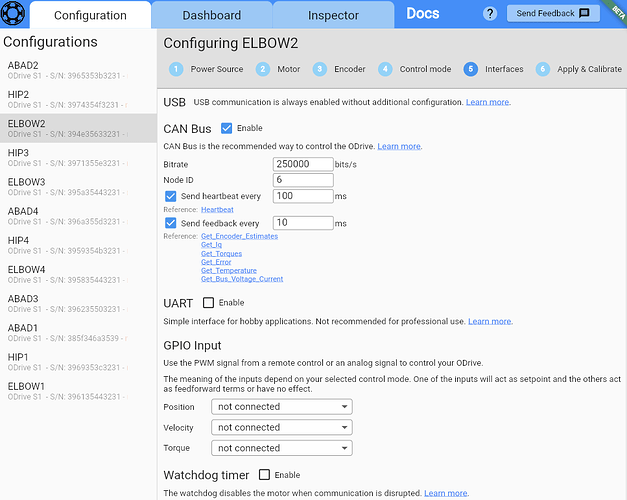

I am experiencing a specific communication issue in my setup, which consists of multiple ODrive S1 controllers connected via a CAN bus, interfaced through an Arduino using an Waveshare SN65HVD230 CAN transceiver. My network includes several ODrive S1 units, each assigned unique CAN IDs and configured to share the same settings (heartbeat every 100ms, signals every 10ms), except for their node IDs. The CAN bus operates at a baud rate of 250000. Arduino is executing the SineWaveCAN example.

Problem Summary:

- When addressing ODrive nodes individually through the Arduino (modifying the node ID in the Arduino code for each test), only nodes with the lowest 3 CAN IDs respond successfully to commands.

- Specifically, the communication issue occurs when attempting to read the bus voltage and current from any node with a higher CAN ID (e.g., #4 and above). The Arduino code gets stuck at the point of sending this request, entering an infinite loop as the request fails.

- This issue persists regardless of the physical order of the nodes on the CAN bus; nodes with higher IDs fail to communicate after the first few.

- All nodes function correctly in smaller groups (3 or fewer), and the issue arises only when more nodes are added to the network, suggesting it’s not an individual node fault.

- The CAN bus is properly terminated, and each node, including the end node, has been verified for correct configuration and termination. The power supply is stable and adequate for all nodes.

Troubleshooting Steps Taken:

- Verified all ODrive S1 nodes are on the latest firmware (0.6.9-1).

- Verified all ODrive S1 nodes work using a USB cable through the webgui’s Dashboard interface.

- Confirmed CAN bus termination and grounding are correctly implemented.

- Tested nodes in smaller group configurations (groups of 2 or 3) using Arduino+CAN, where they all work as expected.

- Tested each node individually using Arduino+CAN, where each worked as expected

- Increased delays and applied a retry system in the Arduino code, which hasn’t resolved the issue.

- Conducted incremental node addition tests, isolating the issue to the handling of higher node IDs.

- In the wiring diagram, its shown that all the nodes are connected from node id #1 being the first in the system, to #12 being last, even when this configuration is reversed, where #12 is first and #1 is last, only the 3 nodes with the lowest IDs seem to work. I have also randomized the configuration (ie, #4, #8, #1, #6, #12) and only the lowest 3 IDs (#4, #1, #6) worked in these configurations as well.

- One thing I had noticed was that before upgrading the firmware on all ODrive S1s, groups up to 6 worked. After upgrading to firmware 0.6.9-1 only groups up to 3 works.

Seeking Support On:

- Insights or solutions for handling communication with nodes that have higher CAN IDs in a network with multiple ODrive S1 units.

- Any known issues or updates related to the ODrive firmware that might affect CAN communication in multi-node setups.

- Recommendations for further diagnostic steps or adjustments to the CAN network configuration to achieve reliable communication with all nodes.

Here is what the wiring schematic looks like:

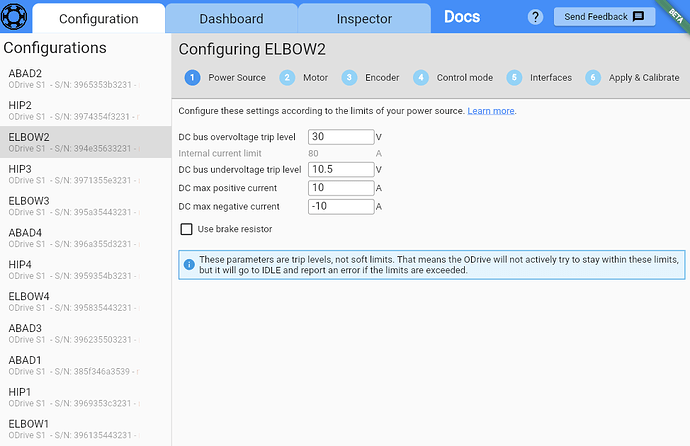

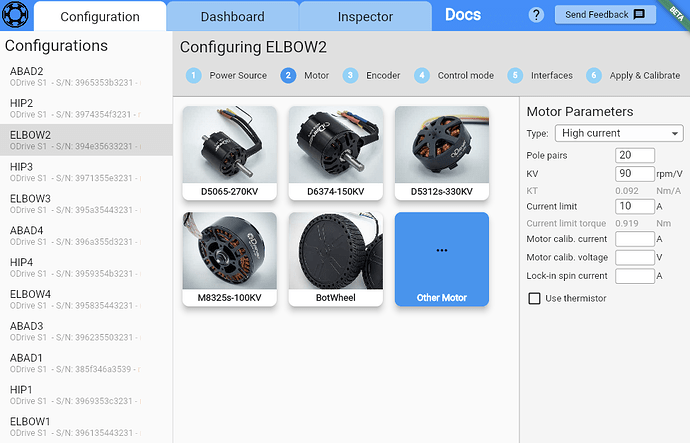

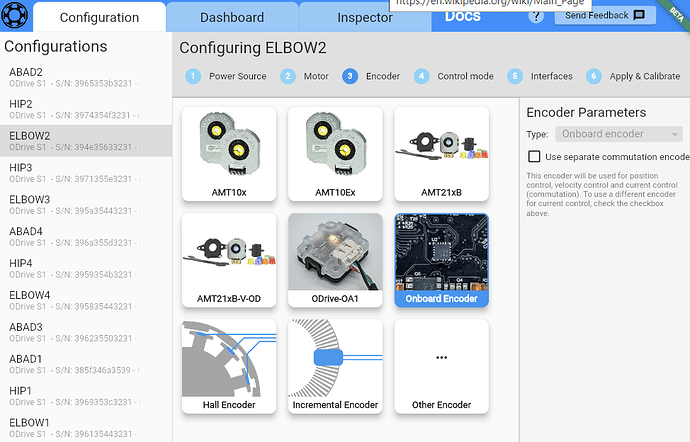

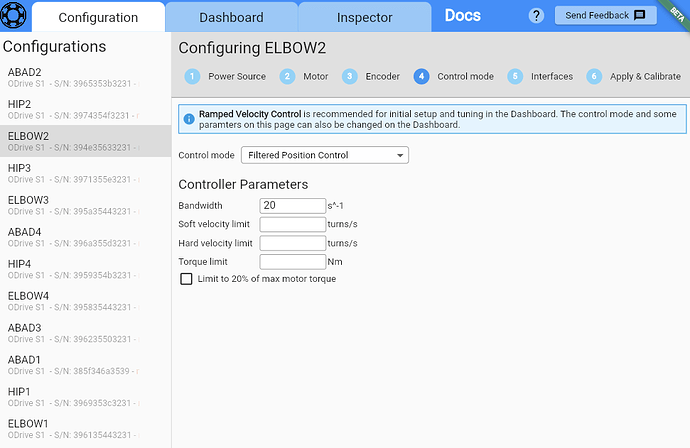

Here is my configuration setup looks like for one of the ODrive S1 nodes in the webgui:

The only difference between all of the nodes is the Node ID, they are different for each node.

Here is the full Arduino code I am using (SineWaveCAN example):

#include <Arduino.h>

#include "ODriveCAN.h"

// Documentation for this example can be found here:

// https://docs.odriverobotics.com/v/latest/guides/arduino-can-guide.html

/* Configuration of example sketch -------------------------------------------*/

// CAN bus baudrate. Make sure this matches for every device on the bus

#define CAN_BAUDRATE 250000

// ODrive node_id for odrv0

#define ODRV0_NODE_ID 3

// Uncomment below the line that corresponds to your hardware.

// See also "Board-specific settings" to adapt the details for your hardware setup.

// #define IS_TEENSY_BUILTIN // Teensy boards with built-in CAN interface (e.g. Teensy 4.1). See below to select which interface to use.

#define IS_ARDUINO_BUILTIN // Arduino boards with built-in CAN interface (e.g. Arduino Uno R4 Minima)

// #define IS_MCP2515 // Any board with external MCP2515 based extension module. See below to configure the module.

/* Board-specific includes ---------------------------------------------------*/

#if defined(IS_TEENSY_BUILTIN) + defined(IS_ARDUINO_BUILTIN) + defined(IS_MCP2515) != 1

#warning "Select exactly one hardware option at the top of this file."

#if CAN_HOWMANY > 0 || CANFD_HOWMANY > 0

#define IS_ARDUINO_BUILTIN

#warning "guessing that this uses HardwareCAN"

#else

#error "cannot guess hardware version"

#endif

#endif

#ifdef IS_ARDUINO_BUILTIN

// See https://github.com/arduino/ArduinoCore-API/blob/master/api/HardwareCAN.h

// and https://github.com/arduino/ArduinoCore-renesas/tree/main/libraries/Arduino_CAN

#include <Arduino_CAN.h>

#include <ODriveHardwareCAN.hpp>

#endif // IS_ARDUINO_BUILTIN

#ifdef IS_MCP2515

// See https://github.com/sandeepmistry/arduino-CAN/

#include "MCP2515.h"

#include "ODriveMCPCAN.hpp"

#endif // IS_MCP2515

#ifdef IS_TEENSY_BUILTIN

// See https://github.com/tonton81/FlexCAN_T4

// clone https://github.com/tonton81/FlexCAN_T4.git into /src

#include <FlexCAN_T4.h>

#include "ODriveFlexCAN.hpp"

struct ODriveStatus; // hack to prevent teensy compile error

#endif // IS_TEENSY_BUILTIN

/* Board-specific settings ---------------------------------------------------*/

/* Teensy */

#ifdef IS_TEENSY_BUILTIN

FlexCAN_T4<CAN1, RX_SIZE_256, TX_SIZE_16> can_intf;

bool setupCan() {

can_intf.begin();

can_intf.setBaudRate(CAN_BAUDRATE);

can_intf.setMaxMB(16);

can_intf.enableFIFO();

can_intf.enableFIFOInterrupt();

can_intf.onReceive(onCanMessage);

return true;

}

#endif // IS_TEENSY_BUILTIN

/* MCP2515-based extension modules -*/

#ifdef IS_MCP2515

MCP2515Class& can_intf = CAN;

// chip select pin used for the MCP2515

#define MCP2515_CS 10

// interrupt pin used for the MCP2515

// NOTE: not all Arduino pins are interruptable, check the documentation for your board!

#define MCP2515_INT 2

// freqeuncy of the crystal oscillator on the MCP2515 breakout board.

// common values are: 16 MHz, 12 MHz, 8 MHz

#define MCP2515_CLK_HZ 8000000

static inline void receiveCallback(int packet_size) {

if (packet_size > 8) {

return; // not supported

}

CanMsg msg = {.id = (unsigned int)CAN.packetId(), .len = (uint8_t)packet_size};

CAN.readBytes(msg.buffer, packet_size);

onCanMessage(msg);

}

bool setupCan() {

// configure and initialize the CAN bus interface

CAN.setPins(MCP2515_CS, MCP2515_INT);

CAN.setClockFrequency(MCP2515_CLK_HZ);

if (!CAN.begin(CAN_BAUDRATE)) {

return false;

}

CAN.onReceive(receiveCallback);

return true;

}

#endif // IS_MCP2515

/* Arduinos with built-in CAN */

#ifdef IS_ARDUINO_BUILTIN

HardwareCAN& can_intf = CAN;

bool setupCan() {

return can_intf.begin((CanBitRate)CAN_BAUDRATE);

}

#endif

/* Example sketch ------------------------------------------------------------*/

// Instantiate ODrive objects

ODriveCAN odrv0(wrap_can_intf(can_intf), ODRV0_NODE_ID); // Standard CAN message ID

ODriveCAN* odrives[] = {&odrv0}; // Make sure all ODriveCAN instances are accounted for here

struct ODriveUserData {

Heartbeat_msg_t last_heartbeat;

bool received_heartbeat = false;

Get_Encoder_Estimates_msg_t last_feedback;

bool received_feedback = false;

};

// Keep some application-specific user data for every ODrive.

ODriveUserData odrv0_user_data;

// Called every time a Heartbeat message arrives from the ODrive

void onHeartbeat(Heartbeat_msg_t& msg, void* user_data) {

ODriveUserData* odrv_user_data = static_cast<ODriveUserData*>(user_data);

odrv_user_data->last_heartbeat = msg;

odrv_user_data->received_heartbeat = true;

}

// Called every time a feedback message arrives from the ODrive

void onFeedback(Get_Encoder_Estimates_msg_t& msg, void* user_data) {

ODriveUserData* odrv_user_data = static_cast<ODriveUserData*>(user_data);

odrv_user_data->last_feedback = msg;

odrv_user_data->received_feedback = true;

}

// Called for every message that arrives on the CAN bus

void onCanMessage(const CanMsg& msg) {

for (auto odrive: odrives) {

onReceive(msg, *odrive);

}

}

void setup() {

Serial.begin(115200);

// Wait for up to 3 seconds for the serial port to be opened on the PC side.

// If no PC connects, continue anyway.

for (int i = 0; i < 30 && !Serial; ++i) {

delay(100);

}

delay(200);

Serial.println("Starting ODriveCAN demo");

// Register callbacks for the heartbeat and encoder feedback messages

odrv0.onFeedback(onFeedback, &odrv0_user_data);

odrv0.onStatus(onHeartbeat, &odrv0_user_data);

// Configure and initialize the CAN bus interface. This function depends on

// your hardware and the CAN stack that you're using.

if (!setupCan()) {

Serial.println("CAN failed to initialize: reset required");

while (true); // spin indefinitely

}

Serial.println("Waiting for ODrive...");

while (!odrv0_user_data.received_heartbeat) {

pumpEvents(can_intf);

delay(90);

}

delay(100);

Serial.println("found ODrive");

// request bus voltage and current (1sec timeout)

Serial.println("attempting to read bus voltage and current");

Get_Bus_Voltage_Current_msg_t vbus;

int retries = 0;

while (!odrv0.request(vbus, 1) && retries < 3) {

Serial.println("Request failed, retrying...");

delay(200); // Increase delay before retry

retries++;

}

if (retries >= 3) {

Serial.println("vbus request failed after retries!");

while (true); // Consider a recovery strategy other than infinite loop

}

Serial.print("DC voltage [V]: ");

Serial.println(vbus.Bus_Voltage);

Serial.print("DC current [A]: ");

Serial.println(vbus.Bus_Current);

Serial.println("Enabling closed loop control...");

while (odrv0_user_data.last_heartbeat.Axis_State != ODriveAxisState::AXIS_STATE_CLOSED_LOOP_CONTROL) {

odrv0.clearErrors();

delay(1);

odrv0.setState(ODriveAxisState::AXIS_STATE_CLOSED_LOOP_CONTROL);

// Pump events for 150ms. This delay is needed for two reasons;

// 1. If there is an error condition, such as missing DC power, the ODrive might

// briefly attempt to enter CLOSED_LOOP_CONTROL state, so we can't rely

// on the first heartbeat response, so we want to receive at least two

// heartbeats (100ms default interval).

// 2. If the bus is congested, the setState command won't get through

// immediately but can be delayed.

for (int i = 0; i < 15; ++i) {

delay(10);

pumpEvents(can_intf);

}

}

Serial.println("ODrive running!");

}

void loop() {

pumpEvents(can_intf); // This is required on some platforms to handle incoming feedback CAN messages

float SINE_PERIOD = 2.0f; // Period of the position command sine wave in seconds

float t = 0.001 * millis();

float phase = t * (TWO_PI / SINE_PERIOD);

odrv0.setPosition(

sin(phase) * 0.2, // position

cos(phase) * (TWO_PI / SINE_PERIOD) * 0.2 // velocity feedforward (optional)

);

// print position and velocity for Serial Plotter

if (odrv0_user_data.received_feedback) {

Get_Encoder_Estimates_msg_t feedback = odrv0_user_data.last_feedback;

odrv0_user_data.received_feedback = false;

Serial.print("odrv0-pos:");

Serial.print(feedback.Pos_Estimate);

Serial.print(",");

Serial.print("odrv0-vel:");

Serial.println(feedback.Vel_Estimate);

}

}