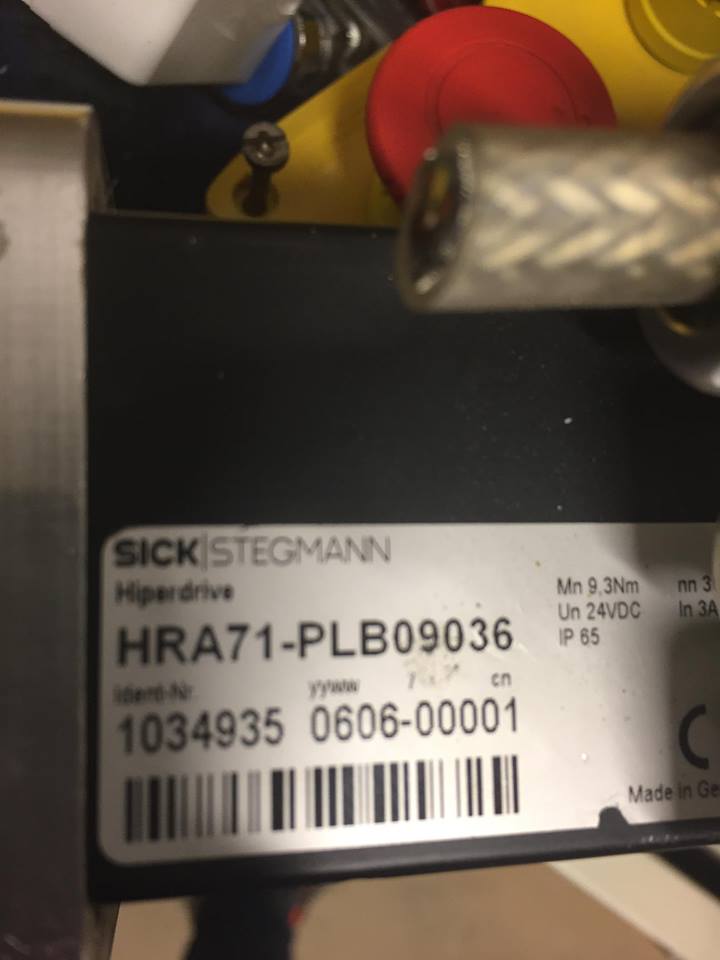

For my large cnc router build I’ve been given four servos intended for Profibus.

If i remove the bus-related pcb’s, I am left with four motors that all have encoders attached.

Do you guys see any issue with controlling the motors with oDrive?

To me it looks like they are 24V bldc motors, but they are slow and powerful.

I have not yet picked them up, so I haven’t looked inside them…

Data sheet:

http://www.insysltd.ru/files/images/IM0016019.pdf

These are the 12Nm version (i.e. XX…09036), which is great. Typ positioning accuracy is ±1.2degrees, which is terrible. 3A max which is terrible.

but they are slow

Well, you’re not wrong there. Lowest possible speed is 11rpm, and norminal speed is 36rpm, which seems terrible in a CNC application. The hope is the low end spec isn’t due to mechanics but rather to their controller not working well at low RPM, but you’d need to see if there’s anything mechanical. With a 5mm pitch, 36rpm only gives you 180mm of travel PER MINUTE. Good heaven that sucks.

Shaft loadings are really low @ 100-400N, which would also terrible in a large/heavy CNC. These are weird motors.

To answer your question more directly - yes I’m sure 24V ODrive would work fine with these motors, but these motors wouldn’t work well on a CNC. I’d pass if I were you.

Thank you, clearly I didn’t have my brain turned on when reading the specs for the motors

Well, beggars can’t be choosers. I’ll have to find some other use for them…

I’ll have to find some other use for them…

12Nm is a lot of torque!!

I’ll have to pick them up and dismantle them first, but max rpm, positioning accuracy ect. MIGHT be due to limitations on the drive electronics.

Blockquote With a 5mm pitch, 36rpm only gives you 180mm of travel PER MINUTE. Good heaven that sucks.

What are you thinking here? a belt sprocket with a circumference of 5mm? That seems a little on the low side

My my belts are HTD 8m, and with a 20tooth pulley (160mm circumference) that equates to 5760 mm/minute or 96mm/sec.

Yes, the positional accuracy might not allow for this, but again, that might be due to limitations in the onboard electronics (that I will scrap regardless)