Our rover team would like to know if optical photogate sensors will work for encoding wheel position driven by a hooverboard motor.

Currently a clear disk (OD 60mm) has black and clear encoder disk (50 black/50 clear segments). This disk is mounted to the inside of 10 inch wheel. Two different opb7030570 photogate sensors are detecting black to clear transitions; one black line while the other sensor see a clear line. Counters in code are tracking the number of ticks as wheel moves.

Here’s the code:

const int encoderIn = 8; // input pin for the interrupter for Rotary

const int encoderIn2 = 7; // input pin for the interrupter for Rotary2

const int statusLED = 13; // Output pin for Status indicator for LED

const int statusLED2 = 11; // Output pin for Status indicator for LED2

const int pulseOutput = 12; // Pulse output pin for external interfacing for Test

const int pulseOutput2 = 10; // Pulse output pin for external interfacing for Test

//int detectState = 0; // Variable for reading the encoder status

int val = 0; // variable for reading the encoder status

int val2 = 0; // variable2 for reading the encoder status2

int count = 0;

int count2 = 0;

int currentState = 0;

int currentState2 = 0;

int previousState = 0;

int previousState2 = 0;

void setup()

{

pinMode(encoderIn, INPUT); //Set pin 8 as input

pinMode(encoderIn2, INPUT); //Set pin 7 as input

pinMode(statusLED, OUTPUT); //Set pin 13 as output

pinMode(statusLED2, OUTPUT); //Set pin 11 as output

pinMode(pulseOutput, OUTPUT); // Set Pin 12 as output

pinMode(pulseOutput2, OUTPUT); // Set Pin 10 as output

Serial.begin(9600);

}

void loop() {

/////////Encoder 1

val = digitalRead(encoderIn); // read input value

if (val == HIGH)

{ // check if the encoder is HIGH (no rotary change)

digitalWrite(pulseOutput,HIGH); // Give a logic-High level output

digitalWrite(statusLED, HIGH); //Turn on the status LED

currentState = 1;

}

else

{

digitalWrite(statusLED, LOW); //Turn off the status LED

digitalWrite(encoderIn, LOW); // turn LED off

currentState = 0;

}

if(currentState != previousState)

{

if(currentState == 1){

count = count + 1;

Serial.print("A: ");

Serial.println(count);

}

previousState = currentState;

delay(1);

}

//////////Encoder 2

val2 = digitalRead(encoderIn2); // read input value

if (val2 == HIGH)

{ // check if the encoder is HIGH (no rotary change)

digitalWrite(pulseOutput2,HIGH); // Give a logic-High level output

digitalWrite(statusLED2, HIGH); //Turn on the status LED

currentState2 = 1;

}

else

{

digitalWrite(statusLED2, LOW); //Turn off the status LED

digitalWrite(encoderIn2, LOW); // turn LED off

currentState2 = 0;

}

if(currentState2 != previousState2)

{

if(currentState2 == 1){

count2 = count2 + 1;

Serial.print("B: ");

Serial.println(count2);

}

previousState2 = currentState2;

delay(1);

}

}

Odrive V3.5 48V board is being used. We would like to use optical encoders as the BLDC motor setup doesn’t allow for access to shaft. Would Odrive motor calibration be possible with two optical encoders and Aurdiuno code seen above? Can A, B and Z encoder inputs on Odrive controller be used with this optical setup?

Thank you kindly for your feedback and time,

John

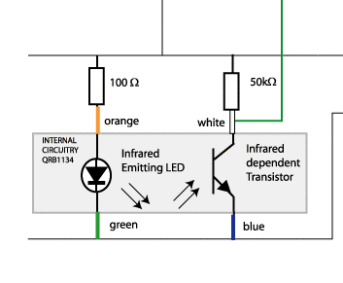

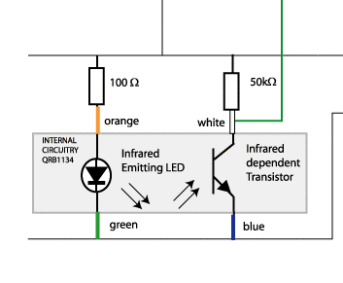

Here is the photogates used to sense the black and white transitions.

https://www.digikey.com/en/datasheets/tt-electronicsoptek-technology/tt-electronicsoptek-technologyopb70370570ahwz