Hi!

I’m trying to use the D6374 150KV to provide a sinusoidal torque input (max 4Hz frequency) to a system in order to run some dynamics experiments. I’d like to be able to control the torque output of the motor as closely as possible so that I can more easily interpret the results of the experiments.

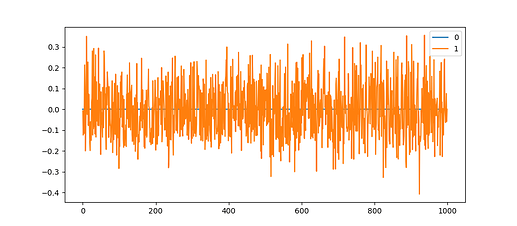

I’m trying to use current control to drive the motor, but I’m finding that the difference between the Iq_setpoint (0) and Iq_measured (1) is a little larger than I’d like:

- Is it possible to tune the current controller to reduce the range of noise from 100-300 mA down to <100 mA? I’ll be driving the motor from 2-20A with a 24V power supply.

- The Getting Started Guide provides a method of tuning the position controller; is there any issue with using the same procedure to tune the current control parameters?

- More generally, is the variation of

Iq_measuredaway fromIq_setpointcaused by measurement noise, or is there a limit on how precisely I can prescribe the current output.

Thanks!

Here’s my motor configuration if it helps:

pre_calibrated = False (bool)

pole_pairs = 7 (int)

calibration_current = 10.0 (float)

resistance_calib_max_voltage = 2.0 (float)

phase_inductance = 2.4107508579618298e-05 (float)

phase_resistance = 0.0507194884121418 (float)

direction = -1 (int)

motor_type = 0 (int)

current_lim = 20.0 (float)

current_lim_tolerance = 1.25 (float)

inverter_temp_limit_lower = 100.0 (float)

inverter_temp_limit_upper = 120.0 (float)

requested_current_range = 20.0 (float)

current_control_bandwidth = 1000.0 (float)