Hi,

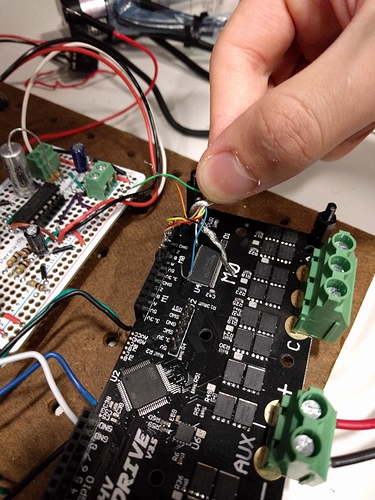

I wrote a python script based off of “odrive_demo.py” to test the ODrive with a Harmonic Drive RSF-Mini 11B motor I’m using (Link to the page here: http://www.harmonicdrive.net/products/rotary-actuators/solid-shaft-actuators/rsf-mini). The motor seems to act appropriately to the calibration sequence to find to the encoder index but when I request a change of state to move to closed loop control and send a position command the odrive doesn’t change states.

Here is my script:

#!/usr/bin/env python3

from __future__ import print_function

import odrive

from odrive.enums import *

import time

import math

# Find a connected ODrive (this will block until you connect one)

print("finding an odrive...")

my_drive = odrive.find_any()

print("Bus voltage is " + str(my_drive.vbus_voltage) + "V")

print("Calibration current is " + str(my_drive.axis0.motor.config.calibration_current) + "A")

# Set some hardware parameters temporarily

print("setting some hardware parameters temporarily")

my_drive.config.brake_resistance = 0.5

my_drive.axis0.motor.config.pole_pairs = 4

my_drive.axis0.encoder.config.cpr = 400000

# Calibrate

print("starting calibration")

my_drive.axis0.encoder.config.use_index = True

my_drive.axis0.requested_state = AXIS_STATE_FULL_CALIBRATION_SEQUENCE

print("waiting for calibration to end...")

while my_drive.axis0.current_state != AXIS_STATE_IDLE:

time.sleep(0.1)

# Closed loop control

print("Changing state to closed loop control")

my_drive.axis0.requested_state = AXIS_STATE_CLOSED_LOOP_CONTROL

while my_drive.axis0.current_state != AXIS_STATE_CLOSED_LOOP_CONTROL:

print("axis errors are:")

print(hex(my_drive.axis0.error))

print("motor errors are:")

print(hex(my_drive.axis0.motor.error))

print("encoder errors are:")

print(hex(my_drive.axis0.encoder.error))

time.sleep(0.1)

print("current state is " + str(my_drive.axis0.current_state))

curr_pos = my_drive.axis0.encoder.pos_estimate

print("current position is " + str(curr_pos) + " ticks")

new_pos = curr_pos + 400000

print("sending to " + str(new_pos) + " ticks")

my_drive.axis0.controller.pos_setpoint = new_pos

The while loop at the end is designed to halt until the odrive to change states to closed loop control but it ends up stuck here forever. Here is the print out:

finding an odrive...

Bus voltage is 23.866186141967773V

Calibration current is 10.0A

setting some hardware parameters temporarily

starting calibration

waiting for calibration to end...

Changing state to closed loop control

axis errors are:

0x41

motor errors are:

0x11

encoder errors are:

0x0

Upon looking into the error codes I found that they correspond to these flags

axis errors are:

ERROR_MOTOR_FAILED = 0x40

ERROR_INVALID_STATE = 0x01

motor errors are:

ERROR_PHASE_RESISTANCE_OUT_OF_RANGE = 0x0001

ERROR_CONTROL_DEADLINE_MISSED = 0x0010

encoder errors are:

no errors

I’d appreciate any help. Thank you!