Hi All,

We’ve been doing some testing on what I think is EMI or some other noise emitted from the motor that travels through our entire chassis affecting un-shielded communication cables. We have shielded our cables which solves the symptom but I would like to eliminate the core issue and looking for feedback.

From what we have observed, if we mount a motor to our aluminum chassis in closed loop control mode we see comms interference with any unshielded cable that comes into contact with the chassis. We have tested this by pulling the comms cable away from the chassis and eliminating the noise, put it back on the chassis and voila noise is back.

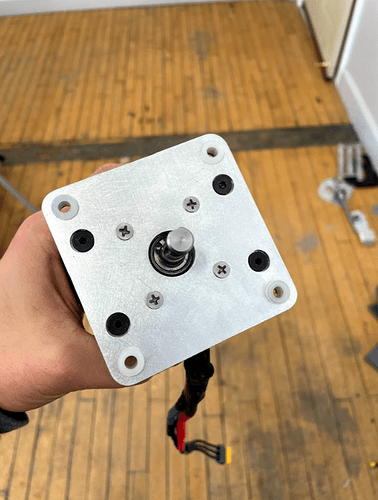

I have attempted to ground the motor plate to the odrive ground as a test to see if that would reduce the noise as many have recommended on the forum but I saw no difference. So far the only way to eliminate the core noise issue is to isolate the motor from the chassis by holding it 5mm away from the chassis in my hand, all other connections still in tact.

Assuming Ferrite beads are the typical solution here, we have very little room and I’m hoping for a more compact solution. Debating wether to just put a 5mm spacer plate out of nylon between the motor and chassis to eliminate the issue entirely.

I’d love any feedback on:

A) What this noise is and how it’s traveling through the chassis

B) If chassis grounding is supposed to eliminate this type of noise or if it’s just a safety precaution

C) Are there are any reasons not to isolate the motors with nylon or some other high heat insulator to remove the noise from traveling through the entire chassis.