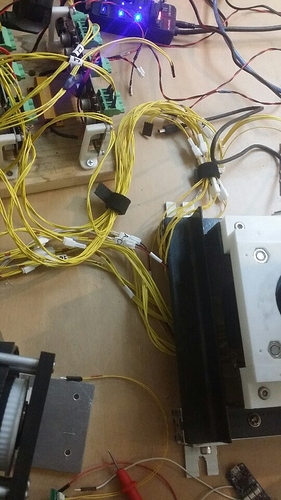

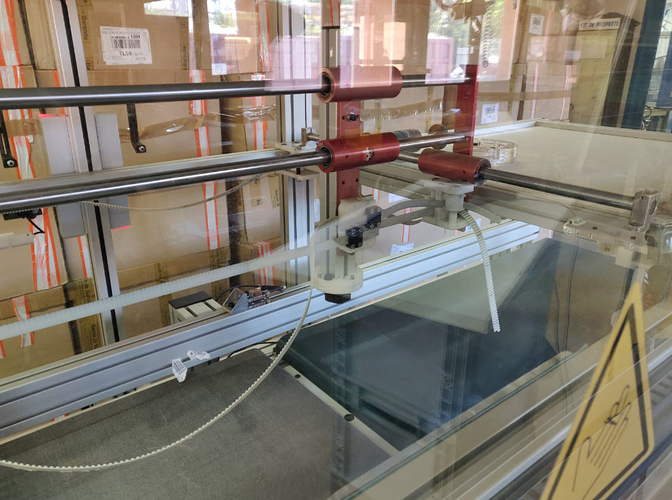

I am trying to stress my odrive corexy system to prove the robustness of the system => I am running in infinite loop a sequence of motor commands

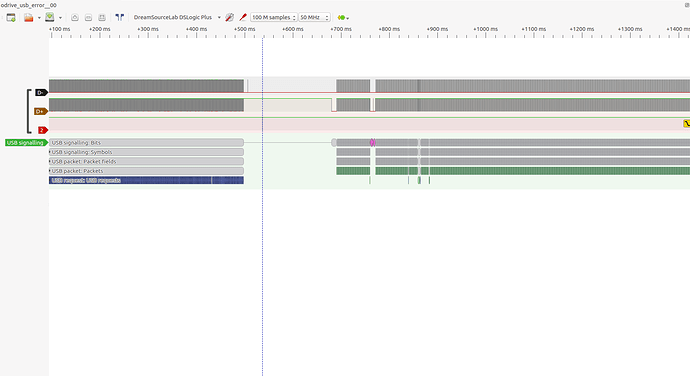

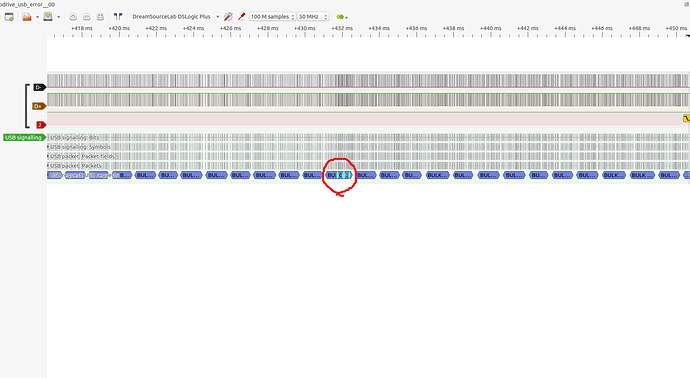

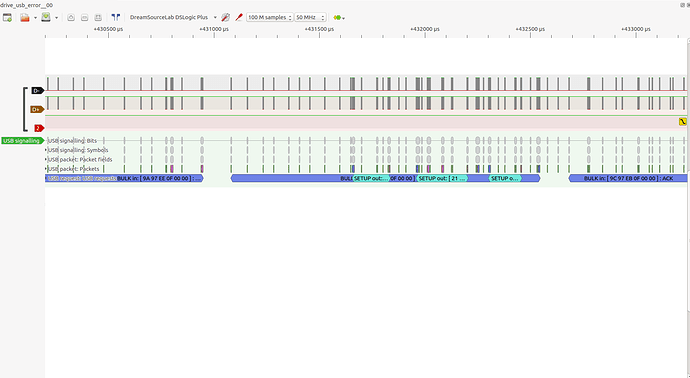

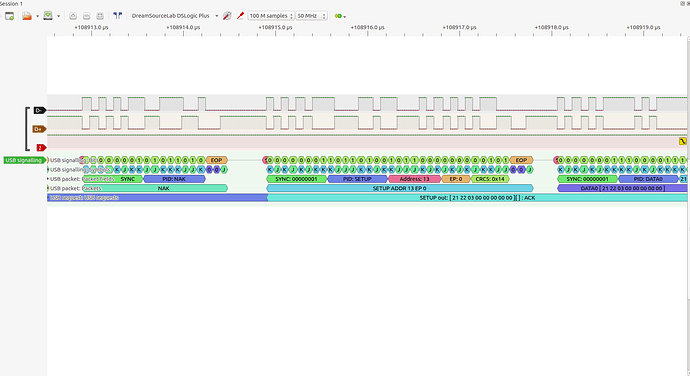

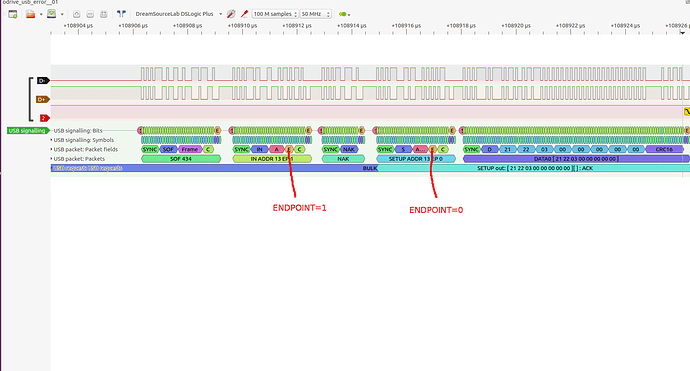

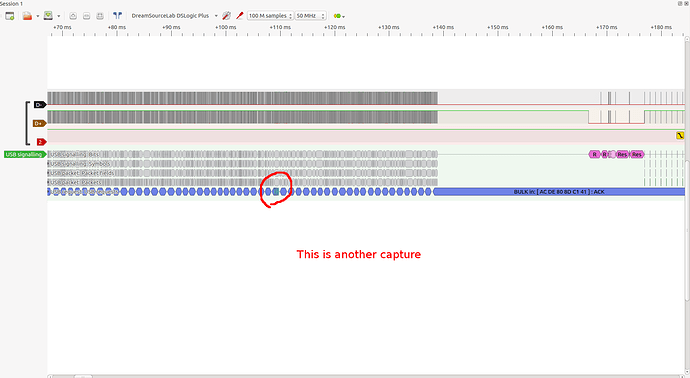

the system runs about fine for about 15-30min but eventually I observe an USB communication issue with odrive than manifests its as I am trying to read motor error code;

AttributeError: ‘RemoteObject’ object has no attribute 'axis0’

Odrive board is directly connected to the a USB port on the PC motherboard (no usb hub)

At the moment when this problems occurs, the exception thrown is not caught, then the python script crashes. And if i try to restart it, most of the time the USB connection never happens and I have to cut on/off the power.

what can i do about this?

some tech details below

firware => 0.4.8.0

hardware => 3.5

variant => 48

bus_voltage => 23.925806045532227

vel_limit => 400000.0 400000.0

pos_gain => 7.0 7.0

vel_gain => 0.0002500000118743628 0.0002500000118743628

vel_integrator_gain => 0.0010000000474974513 0.0010000000474974513

motor_error => ERROR_NO_ERROR ERROR_NO_ERROR

[... after about 15-30min...]

Traceback (most recent call last):

File "automata_v2.2.py", line 166, in <module>

test_cut()

File "automata_v2.2.py", line 160, in test_cut

cut(c)

File "automata_v2.2.py", line 48, in cut

cmd = "G0 X"+str(x)+" Y"+str(y) ; c.send_cmds(cmd) ; time.sleep(t)

File "/root/odrive_test/corexy.py", line 235, in send_cmds

res = self.__handle_cmd(cmd)

File "/root/odrive_test/corexy.py", line 264, in __handle_cmd

return self.__parse_goto(cmd[2:])

File "/root/odrive_test/corexy.py", line 288, in __parse_goto

return self.__goto(target_x, target_y)

File "/root/odrive_test/corexy.py", line 328, in __goto

self.__move_motors(dA_steps, dB_steps)

File "/root/odrive_test/corexy.py", line 545, in __move_motors

m0 = self.__get_motor_error_name(self.my_odrive.axis0.motor.error)

File "/usr/local/lib/python3.5/dist-packages/fibre/remote_object.py", line 245, in __getattribute__

return object.__getattribute__(self, name)

AttributeError: 'RemoteObject' object has no attribute 'axis0'

root@MTBD00694:~/odrive_test#

root@MTBD00694:~/odrive_test# python3 -m pip show odrive

Name: odrive

Version: 0.4.8

Summary: Control utilities for the ODrive high performance motor controller

Home-page: https://github.com/madcowswe/ODrive

Author: Oskar Weigl

Author-email: oskar.weigl@odriverobotics.com

License: MIT

Location: /usr/local/lib/python3.5/dist-packages

Requires: pywin32, requests, PyUSB, ipython, PySerial, IntelHex, matplotlib

Required-by:

root@MTBD00694:~/odrive_test#

root@MTBD00694:~/odrive_test# python3 -i

Python 3.5.2 (default, Nov 12 2018, 13:43:14)

[GCC 5.4.0 20160609] on linux

Type "help", "copyright", "credits" or "license" for more information.

>>> exit()

root@MTBD00694:~/odrive_test# cat /etc/lsb-release

DISTRIB_ID=Ubuntu

DISTRIB_RELEASE=16.04

DISTRIB_CODENAME=xenial

DISTRIB_DESCRIPTION="Ubuntu 16.04.4 LTS"

root@MTBD00694:~/odrive_test#