Basically, I have a recumbent bike and a particular problem of road imperfections beating my bad back and causing nasty cramps - even with full suspension and wide tires.

The problems is mostly with the back, and there is not a whole lot of load on the seat back that gives me trouble.

I’m planning an electric assist using VESCs (a blown electric transmssion even, maybe - I’ve got a pretty well-working pedal pegenerator with ~85% efficiency), so I’ll have a large (24v though) battery anyway.

Is it realistic to stabilize my seat back against bumps using similar principles like active camera stabilisation rigs work, using inexpencive drone/eskater motors? I’m very new to this (just some arduino programming, I’ve made myself gear shifter), so I want a sanity check before I dive into it. I do not need whole lot of ‘travel’, just a few cm to isolate me from vibrations would be cool - I have suspension that works pretty well for larger hits, but bad asphalt gets me… maybe something like a screw actuator, maybe simply using m10/m12 bolt and some grease? This sounds vaguely ok as far as needed mechanical reduction and travel goes.

EDIT:

Ok, run some numbers:

Assume 40 kmh, 700mm diameter rear wheel, 30mm sharp bump - that’s ‘angle of attack’ of 12 deg at the wheel (deflection of tire will make it less I presume, but hard to calculate).

Sin 12 deg ~ 0.2

40kmh in mm/sec - 11111 mm/sec

So, I want the system to move at least 11111*0.2 = 2300 mm/sec

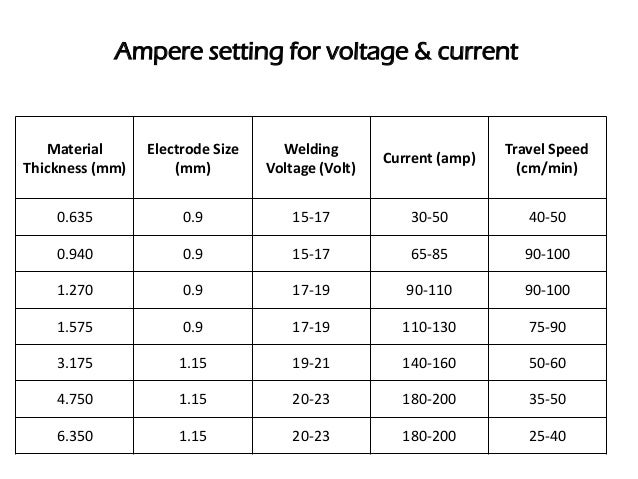

A 2mm pitch lead screw (should work better than a simple bolt): 2mm/revolution

270kv motor (5065) * 24v = 6480 rpm

108 rps

216 mm/sec

Ouch, that’s like an order of magnitude less than I want. Also, what about torque?

Assume about 30 kg of load on the seat back…

Convert newton-meters into linear newtons given 2mm pitch:

2 Pi * r /pitch

2 * 3.14 * 1 / 0.002 = 3141

Erm, that a ton of mechanical advantage (makes sense)

So, 1 nm will produce 3141 newton of force, or 300 kg, discregarding friction. Cool, that’s way more than I need.

Also, found this site, it does take friction into account:

Ok, seems I need just 0.3nm to rise 300N, and wil take about 10amps to produce… but that seems nearly 10 times slower than needed unless accounting for much smaller imperfections. I’ll need something like small RC 2000 or so KV motor, and use accordingly larger currents (though I presume feeding them off 24v will make them exceed max RPM well, maybe acounting for smaller imperfections/less speed plus tire defection should make the system still useable with a motor of, say, 1000 kv - or using a step up gearing using a motor I have - though it will complicate matters a bit… though I also need to account for voltage drop… sigh).

Also, there is a question of critical lead speed… mine will be fairly short, online calculator give me around 30k rpm - so, again, 1000 kv…

Or I can use a ‘4 start’ lead screw - as far as I understand, that will increase effective pitch to 8mm - so I’ll be able to use 270kv motor and get a useful 900mm/s speed out of the system while driving it directly, and still stay within Odrive/motor current limits.

A robust system of endstops will need to implemented, of course… and some way to make the system reset to ‘midpoint’… what’s cool by manipulating that ‘midpoint’ you can use adjustable geometry for the seat, that can be quite handly.

Anyway, this exersize game me an appreciation for speeds and forces involved.

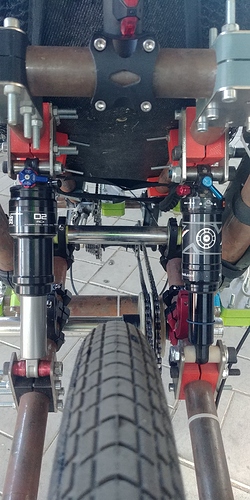

I think it may actually be possible to use such a system as ‘electromechanical’ suspension. Using it as an extra means of electric regenerative damping when paired with cheap shock seems easy, you just need a ball screw to minimise friction (you certainly DO want this system to be backdriveable).

If I and my monster of a bike were lighter, I think it might actually be possible to emulate something like Bose suspension using, say, 1/5 RC car motors that are high speed and capable of swallowing huge currents:

Maybe I should try that sometime, should be a fun project.

Maybe eventually I’ll get myself a proper shop, but not now.

Maybe eventually I’ll get myself a proper shop, but not now.