Im using a Gimbal motor T-Motor 4106 and if i have the motor type at HighCurrent it fails calibration. If I change the motor Type to Gimbal then it calibrates fine. The weird thing is inorder for it too calibrate, i first need to run a calibration with HighCurrent Active. When it fails for resistance_XXX then i go to inspector change motortype to Gimbal then it calibrates fine.

Hi! Typically the Micro should be run in HIGH_CURRENT mode – GIMBAL is a misnomer, we’re renaming it.

What supply voltage are you using? I can recommend some calibration parameters from that.

18 volts will hopefully get up to 24v.

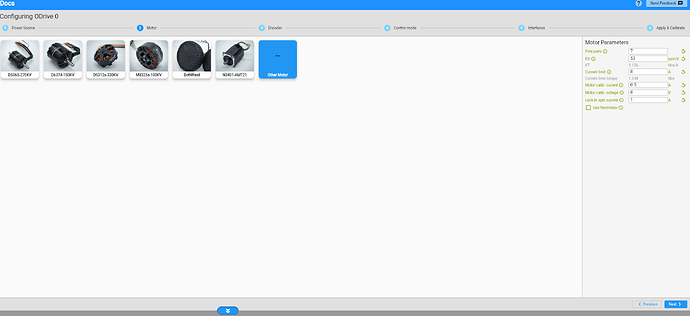

Try 0.5A calib current, 8V calib voltage, 1A lock-in spin current.

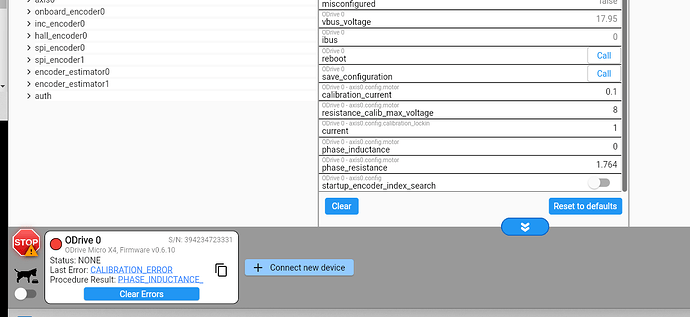

With those settings I Get a Phase_Inductance_Out of range error

If you go to the inspector tab after calibration fails, and search for phase_inductance, then drag it to the center, does it show a nonzero value? Or does it show either 0 or NaN?

Shows 0.

In that case, try lowering calib. current to 0.25A – if that still doesn’t work, try 0.1A.

I understand that gimbal type motor is a Misnomer but what is it changing in the calculations currently?

If i run calib

A :1

V :5

Lock In : 3

It calibrates fine and runs velocity and position control great in Dashboard.

Phase_Inductance is still set to 0 after calibration using gimbal.

Neither of those worked and phase_inductance still reading to 0

So, gimbal mode will control the motor by directly setting the voltage through the motor, instead of doing closed-loop control on current. This is typically required when the motor’s maximum continuous current is much much lower (5-10%) of the ODrive’s rated current – it was originally developed for high-current ODrives such as the S1 and Pro (which can do 40A and 120A of current respectively). Since the Micro is designed to control low-current motors, it’s not required to use gimbal mode. There’s nothing strictly wrong with it, but it’ll result in a speed limitation and potentially less accurate torque measurements than using HIGH_CURRENT mode. That being said, if it works for your applications, then that’s great, and sounds like that may be the easy path forward here.

Just note to set the phase resistance value to 7.65, not 15.3 (t-motor gives phase-phase resistance, which is 2x the phase-neutral resistance value the ODrive uses).

Gotcha, I think I know the issue, I’ll make a PR internally and it should be fixed in firmware 0.6.11 when it’s released ![]()

I think we removed that for this exact reason, but if you’re still getting the phase inductance issues, that’s really not helpful.

Hang on one second, making you a custom firmware build.

Okay, give this a shot:

You can install it in the GUI’s firmware update tab, from there please retry calibration, and if it works let me know what the phase_inductance value ended up being in the inspector.

Okay something strange. If i request calibration through the Config tools it fails.

I just ran calibration through the inspector using

Motortype: high current

Cal current : 1

Cal Voltage :5

Lockin Current :3

and it works. Phase inductance reads .007101

Try this - ODriveFirmware_Micro_BypassInductanceLimits.elf - Google Drive

Note that this just removes all limits/checking on phase inductance, so please try it at 0.5/0.25/0.1 and show me the phase_inductance values for each – but try it by setting requested_state to MOTOR_CALIBRATION in the inspector tab as opposed to using the GUI configuration flow, I’ll want to check that the phase inductance values are sensible / won’t cause issues.

EDIT: nevermind ![]()

Oh interesting. Okay, 7mH is quite high but not excessive, that makes sense. Can you show the parameter dump on the final page of the inspector?

inspector tab or Configuration Tab?

Im assuming Configuration Tab?

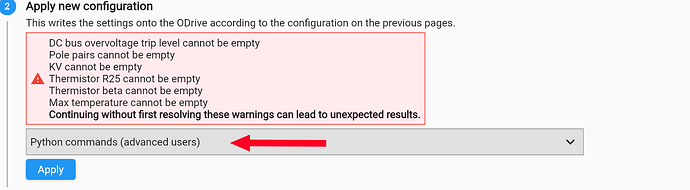

odrv = odrv0

odrv.config.dc_bus_overvoltage_trip_level = 20

odrv.config.dc_bus_undervoltage_trip_level = 6

odrv.config.dc_max_positive_current = math.inf

odrv.config.dc_max_negative_current = -math.inf

odrv.axis0.config.motor.motor_type = MotorType.HIGH_CURRENT

odrv.axis0.config.motor.pole_pairs = 7

odrv.axis0.config.motor.torque_constant = 0.15603773584905659

odrv.axis0.config.motor.current_soft_max = 8

odrv.axis0.config.motor.current_hard_max = 10

odrv.axis0.config.motor.calibration_current = 0.5

odrv.axis0.config.motor.resistance_calib_max_voltage = 8

odrv.axis0.config.calibration_lockin.current = 1

odrv.axis0.motor.motor_thermistor.config.enabled = False

odrv.axis0.controller.config.control_mode = ControlMode.POSITION_CONTROL

odrv.axis0.controller.config.input_mode = InputMode.TRAP_TRAJ

odrv.axis0.controller.config.vel_limit = 100

odrv.axis0.controller.config.vel_limit_tolerance = 2

odrv.axis0.config.torque_soft_min = -math.inf

odrv.axis0.config.torque_soft_max = math.inf

odrv.axis0.trap_traj.config.accel_limit = 10

odrv.axis0.controller.config.vel_ramp_rate = 10

odrv.axis0.trap_traj.config.vel_limit = 8

odrv.axis0.trap_traj.config.decel_limit = 10

odrv.can.config.protocol = Protocol.SIMPLE

odrv.can.config.baud_rate = 250000

odrv.axis0.config.can.node_id = 63

odrv.axis0.config.can.heartbeat_msg_rate_ms = 100

odrv.axis0.config.can.encoder_msg_rate_ms = 0

odrv.axis0.config.can.iq_msg_rate_ms = 0

odrv.axis0.config.can.torques_msg_rate_ms = 0

odrv.axis0.config.can.error_msg_rate_ms = 0

odrv.axis0.config.can.temperature_msg_rate_ms = 0

odrv.axis0.config.can.bus_voltage_msg_rate_ms = 0

odrv.axis0.config.enable_watchdog = False

odrv.inc_encoder0.config.enabled = True

odrv.axis0.config.load_encoder = EncoderId.INC_ENCODER0

odrv.axis0.config.commutation_encoder = EncoderId.INC_ENCODER0

odrv.inc_encoder0.config.cpr = 10240

odrv.axis0.commutation_mapper.config.use_index_gpio = True

odrv.axis0.pos_vel_mapper.config.use_index_gpio = True

odrv.config.gpio4_mode = GpioMode.DIGITAL

odrv.axis0.pos_vel_mapper.config.index_gpio = 4

odrv.axis0.pos_vel_mapper.config.index_offset = 0

odrv.axis0.pos_vel_mapper.config.index_offset_valid = True

odrv.axis0.commutation_mapper.config.index_gpio = 4