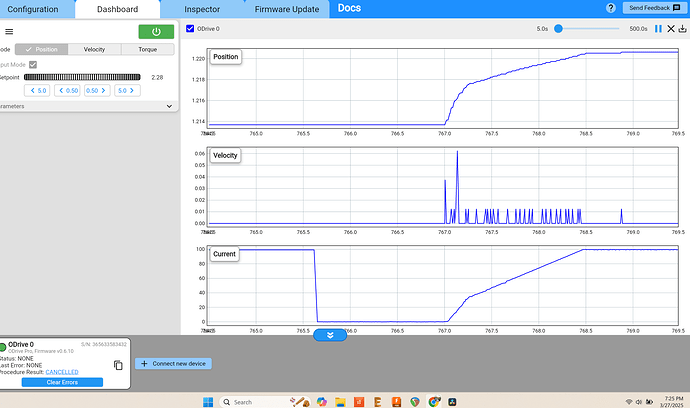

Hello, I am attempting to test my servo motor’s maximum instantaneous torque. Although I have set the current limit to 150 amps in the motor parameters section of the GUI, it appears that the Odrive Pro is limiting the current to 100 amps. Is there any way to output more than 100 amps for a short time such as 2-3 seconds?

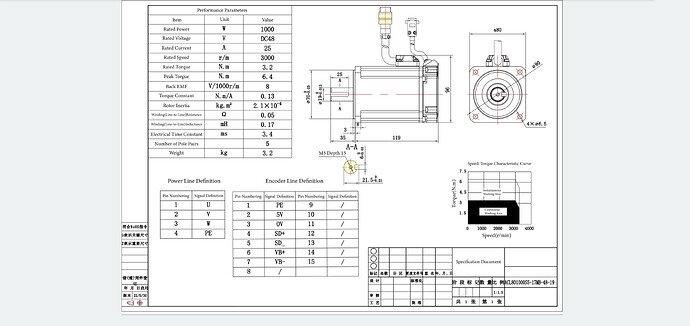

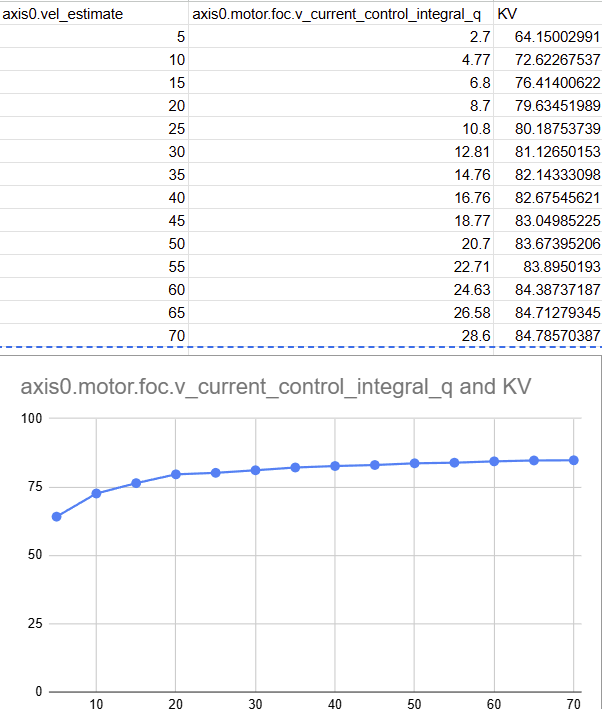

I think I have tried all of the different control modes already, but what is recommended for testing the max instantanous torque? So far my highest measured torque (externally using a scale and moment arm) has been 8.4 Nm and this is using position drive mode - the motor doesn’t turn during my test the torque arm is placed against a scale so as i increase the position the torque and amps ramp up but the motor cannot turn. 8.4 Nm is the torque measured externally when the GUI plots 100 amps. (Which also suggests that the advertised 0.13 Nm/A torque constant is wrong.

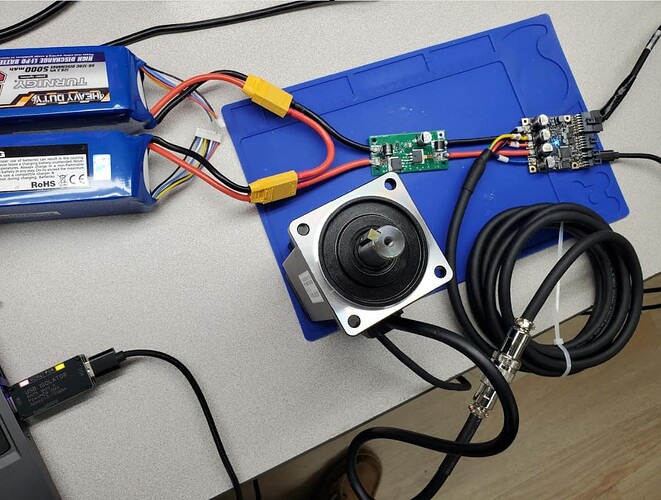

My clamp meter shows that the Odrive draws 30 amps from the battery when the GUI output shows 100 amps. Lastly my motor is rated for 48V and my supply (14s = [2 x 7s]) is presently charged to 54V. I was thinking that driving the motor with a slightly higher supply voltage could eek a bit more torque out of it; is there any validity to that hypothesis?

My motors rated torque is 3.2 Nm - its a standard 1000W/48V servo in an 80mm frame. The max instantaneous theoretical torque is 9.6. How practical is it that I could hit that 9.6?

Thanks!

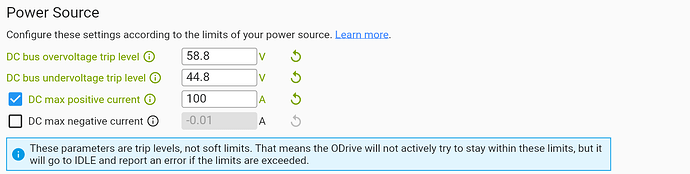

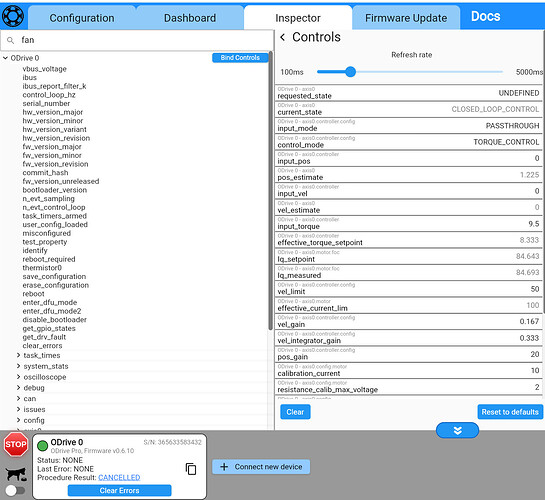

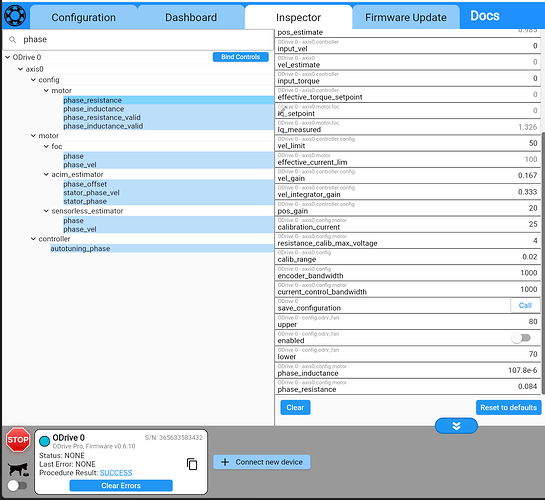

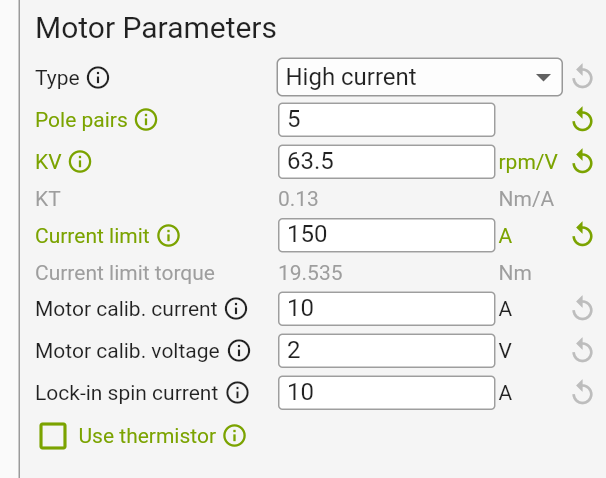

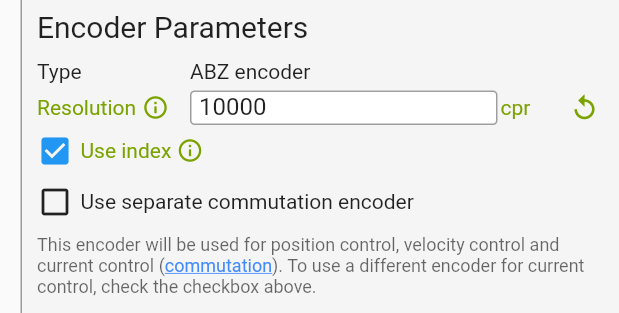

Edit: 2025-03-28; adding configuration text:

odrv = odrv0

odrv.config.dc_bus_overvoltage_trip_level = 58.8

odrv.config.dc_bus_undervoltage_trip_level = 44.8

odrv.config.dc_max_positive_current = 100

odrv.config.dc_max_negative_current = -math.inf

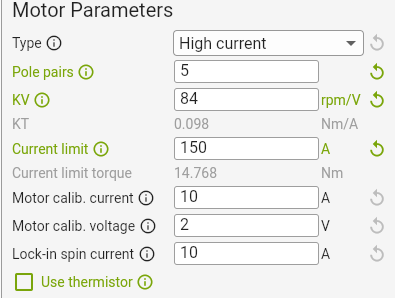

odrv.axis0.config.motor.motor_type = MotorType.HIGH_CURRENT

odrv.axis0.config.motor.pole_pairs = 5

odrv.axis0.config.motor.torque_constant = 0.13023622047244093

odrv.axis0.config.motor.current_soft_max = 150

odrv.axis0.config.motor.current_hard_max = 170

odrv.axis0.config.motor.calibration_current = 10

odrv.axis0.config.motor.resistance_calib_max_voltage = 2

odrv.axis0.config.calibration_lockin.current = 10

odrv.axis0.motor.motor_thermistor.config.enabled = False

odrv.axis0.controller.config.control_mode = ControlMode.POSITION_CONTROL

odrv.axis0.controller.config.input_mode = InputMode.PASSTHROUGH

odrv.axis0.controller.config.vel_limit = 50

odrv.axis0.controller.config.vel_limit_tolerance = 1.5

odrv.axis0.config.torque_soft_min = -math.inf

odrv.axis0.config.torque_soft_max = math.inf

odrv.can.config.protocol = Protocol.NONE

odrv.axis0.config.enable_watchdog = False

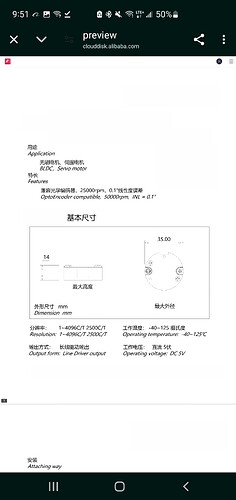

odrv.inc_encoder0.config.enabled = True

odrv.axis0.config.load_encoder = EncoderId.INC_ENCODER0

odrv.axis0.config.commutation_encoder = EncoderId.INC_ENCODER0

odrv.inc_encoder0.config.cpr = 10000

odrv.axis0.commutation_mapper.config.use_index_gpio = True

odrv.axis0.pos_vel_mapper.config.use_index_gpio = True

odrv.config.gpio7_mode = GpioMode.DIGITAL

odrv.axis0.pos_vel_mapper.config.index_gpio = 7

odrv.axis0.pos_vel_mapper.config.index_offset = 0

odrv.axis0.pos_vel_mapper.config.index_offset_valid = True

odrv.axis0.commutation_mapper.config.index_gpio = 7

odrv.config.enable_uart_a = False