Hello all,

Hope you are all having a good weekend.

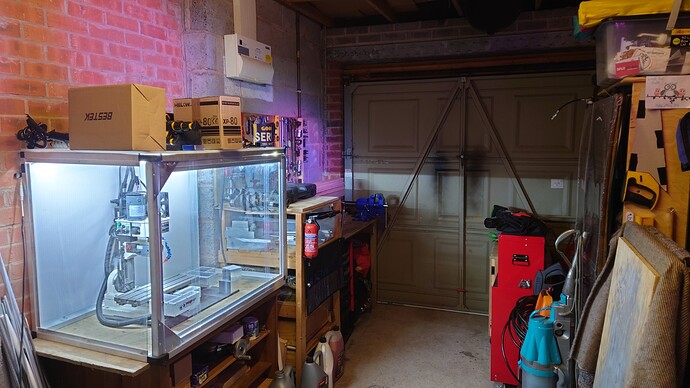

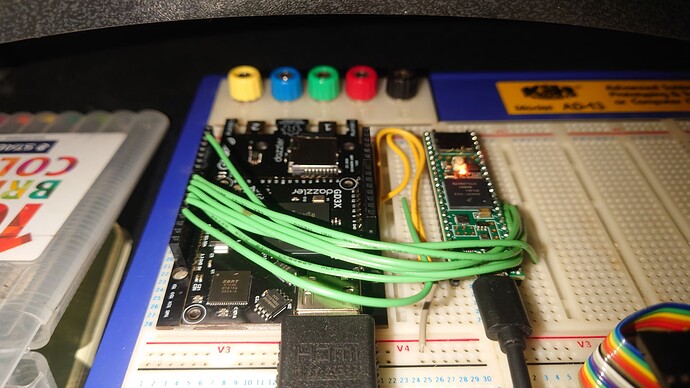

I know I haven’t posted in a while, so thought I’d give an update and share the CNC mill development so far, basically, I’m now going to control the ODrive with a Teensy 4.1 and use a Gameduino 3x Dazzler to display on a Portrait oriented HDMI display.

Ye Olde controller that can be frustrating to use…

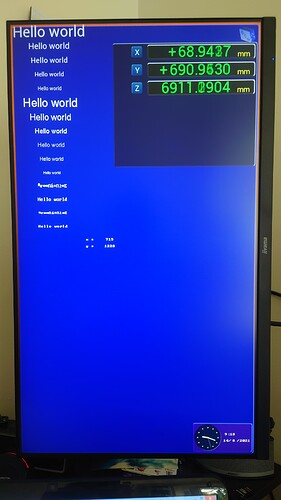

New Display using the Teensy 4.1 controlling the Gameduino 3x Dazzler…

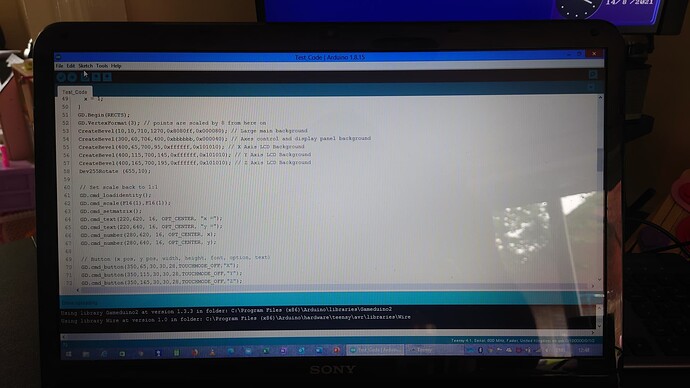

Programming the Teensy (easier than I thought).

Teensy 4.1 connected to the Gameduino 3x Dazzler.

As you can see in the pictures, I am currently upgrading the CNC controller and display for seeing all the information easily and with a resolution of 720 x 1280.

This will have so many positives when it comes to machining out parts, not only speed, but also showing all aspects of the machine while it works.

The main idea behind getting this setup is so I can fit a display like this in the MGF and monitor everything about the MGF Electric Power Unit, what do you think? Could look a little Tesla’ish.

What’s the cost though? Well, here is the list: -

-

£26.48 - Teensy 4.1 microprocessor

-

£40 - Second hand monitor (still in the post)

-

£43.99 - Gameduino 3x Dazzler with HDMI out

-

Some time programming, drawing the screen, generating menus and integrating it all in the machine.

So all this full control and modern looking display system for £110.47 plus a little programming time, where basic controllers can set you back £2500 plus on a home CNC. Also, this will double as the display in the MGF :-D.

What’s the difference then between what I have at the moment? Well, the current microprocessor is an Arduino Mega 2560 and these are the differences: -

-

Arduino has 256KB of flash (program storage) where the Teensy has 8MB

-

Arduino has 4 serial ports where the Teensy has 8 (better for connecting to all the MGF devices)

-

Arduinos benchmark speed is 7 where the Teensy is 2381

-

Arduino runs at 16MHz where the Teensy runs at 600MHz (and is overclockable to love 1MHz with cooling)

-

Teensy has a Micro SD card slot

-

Teensy has a Real Time Clock built in (good for the MGF project also)

-

Teensy is, well, Tiny

-

I think the display difference is fairly self explanatory, where every time I need to make changes to a milled part I have to go through the extensive menu system with only 8 lines of text. The Gameduino allows me to create pop up windows to easily select programs and features.

As you can see this is a little extra work than I was planning, although will make all the projects even more fun and easy to use. I only received the Teensy and Gameduino on Wednesday and have already got it to start looking like a CNC display.

Now the Garage is sorted, the MGF has been over here and the mill is progressing nicely, I should be able to move things along so much more (all settled in now).

Has anyone else tried this type of configuration? I think it makes the machine look ultra modern.

Kind regards,

Neil.

.

.

.

.

, although it’s on its way down to my nephew as we type

, although it’s on its way down to my nephew as we type  .

.