Hello.

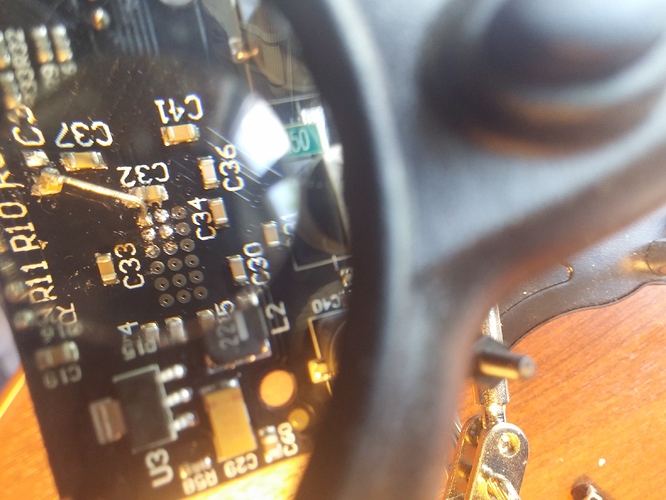

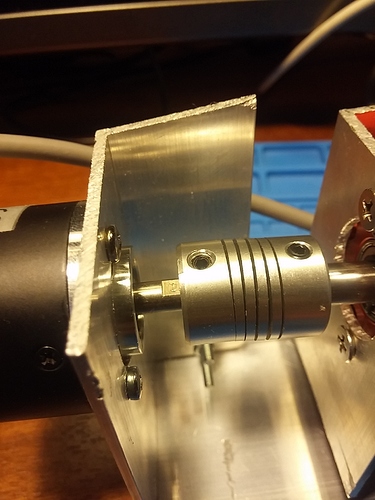

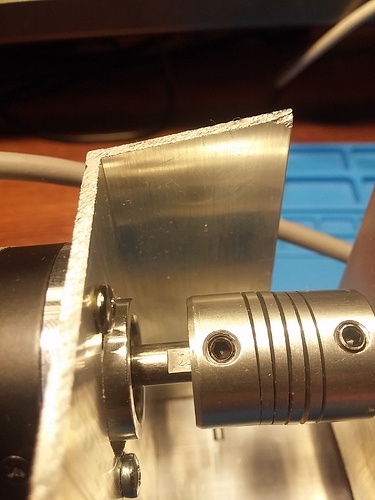

I’ve tested the Odrive 3.5 with the Z index encoder OMRON 2500 cpr and motor N5065.

Strange behavior repeats.

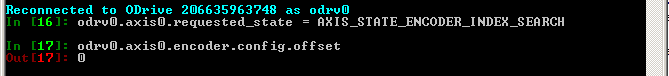

startup_motor_calibration - is ok

startup_encoder_index_search - is ok

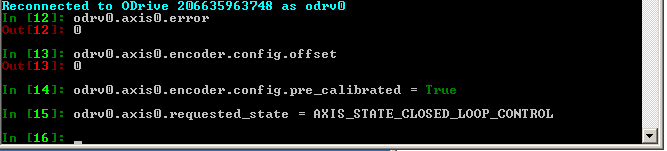

But if after startup send

odrv0.axis0.requested_state = AXIS_STATE_CLOSED_LOOP_CONTROL

then there is uncontrolled N5065 rotation

And after this odrv0.axis0.error returns code 49

Here is the video

Here is the json i used as backup-config

{

“config”: {

“brake_resistance”: 2,

“enable_uart”: true,

“enable_i2c_instead_of_can”: false,

“enable_ascii_protocol_on_usb”: true,

“dc_bus_undervoltage_trip_level”: 8,

“dc_bus_overvoltage_trip_level”: 51.840003967285156

},

“axis0”: {

“config”: {

“startup_motor_calibration”: true,

“startup_encoder_index_search”: true,

“startup_encoder_offset_calibration”: false,

“startup_closed_loop_control”: false,

“startup_sensorless_control”: false,

“enable_step_dir”: false,

“counts_per_step”: 2,

“ramp_up_time”: 0.4000000059604645,

“ramp_up_distance”: 12.566370964050293,

“spin_up_current”: 10,

“spin_up_acceleration”: 400,

“spin_up_target_vel”: 400

},

“motor”: {

“config”: {

“pre_calibrated”: false,

“pole_pairs”: 7,

“calibration_current”: 10,

“resistance_calib_max_voltage”: 1,

“phase_inductance”: 0,

“phase_resistance”: 0,

“direction”: 1,

“motor_type”: 0,

“current_lim”: 10,

“requested_current_range”: 70

}

},

“controller”: {

“config”: {

“control_mode”: 3,

“pos_gain”: 20,

“vel_gain”: 0.0005000000237487257,

“vel_integrator_gain”: 0.0010000000474974513,

“vel_limit”: 20000

}

},

“encoder”: {

“config”: {

“mode”: 0,

“use_index”: true,

“pre_calibrated”: true,

“idx_search_speed”: 10,

“cpr”: 10000,

“offset”: 0,

“offset_float”: 0,

“calib_range”: 0.019999999552965164

}

}

},

“axis1”: {

“config”: {

“startup_motor_calibration”: false,

“startup_encoder_index_search”: false,

“startup_encoder_offset_calibration”: false,

“startup_closed_loop_control”: false,

“startup_sensorless_control”: false,

“enable_step_dir”: false,

“counts_per_step”: 2,

“ramp_up_time”: 0.4000000059604645,

“ramp_up_distance”: 12.566370964050293,

“spin_up_current”: 10,

“spin_up_acceleration”: 400,

“spin_up_target_vel”: 400

},

“motor”: {

“config”: {

“pre_calibrated”: false,

“pole_pairs”: 7,

“calibration_current”: 10,

“resistance_calib_max_voltage”: 1,

“phase_inductance”: 0,

“phase_resistance”: 0,

“direction”: 1,

“motor_type”: 0,

“current_lim”: 10,

“requested_current_range”: 70

}

},

“controller”: {

“config”: {

“control_mode”: 3,

“pos_gain”: 20,

“vel_gain”: 0.0005000000237487257,

“vel_integrator_gain”: 0.0010000000474974513,

“vel_limit”: 20000

}

},

“encoder”: {

“config”: {

“mode”: 0,

“use_index”: false,

“pre_calibrated”: false,

“idx_search_speed”: 10,

“cpr”: 8192,

“offset”: 0,

“offset_float”: 0,

“calib_range”: 0.019999999552965164

}

}

}

}