Hello all,

I wanted to share the new design of the opentorque project with you. The original version was created by Gabrael Levine, more info here.

Skyentific had allready made some small improvements, so I started this redesign with his model.

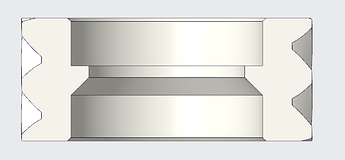

The original design uses a very expensive and hard to find cross roller bearing. This is the main reason for the new version, which now only uses cheap bearings. But eventually I have changed allmost every part in this design, and added improvements where I could.

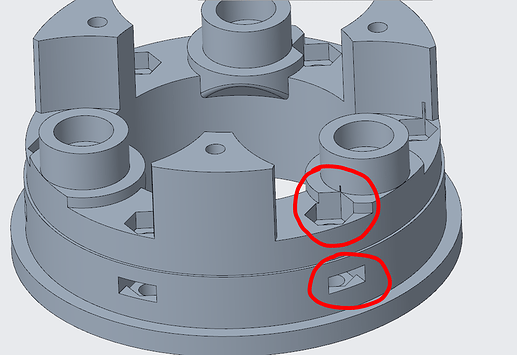

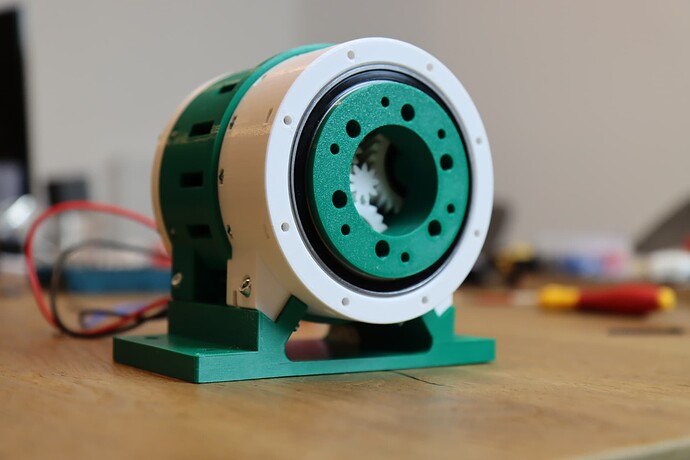

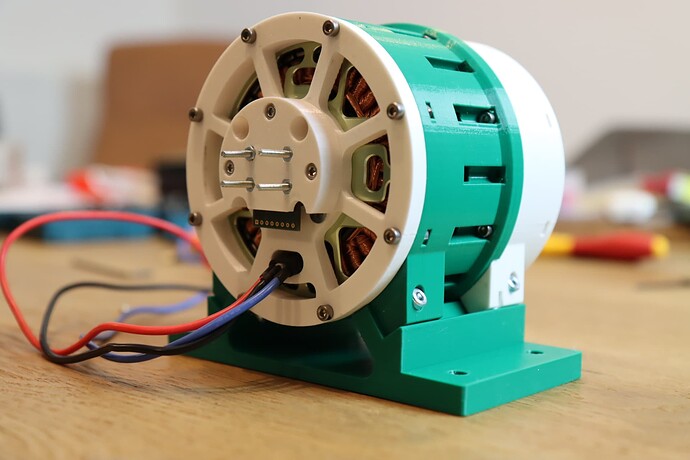

Here is a picture of the final design:

In what follows I will quickly run through the assembly process.

BOM (what you will need)

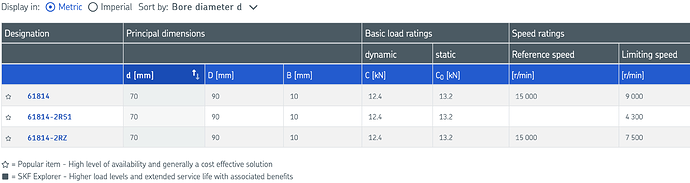

- ball bearing 70mm ID, 90mm OD, 10mm thickness (2x), for example see here

- ball bearing 15mm ID x 28mm OD x 7mm thickness (6x) for example see here

- M3 x 20mm, socket head (19x)

- M3 nut (32x)

- M3 flat head x 20mm (14x)

- M3 flat head x 10mm (10x)

- M2.5 x 10mm, socket head (4x)

- M2.5 nut (4x)

- M4 flat head x 10mm (4x)

- M4 socket head x 20mm (4x)

- M4 nut (10x)

- AMS AS5048A-TS_EK_AB encoder

- Herlea X8318S KV100 (Multistar 9235) brushless motor (or similar, see thread here )

- cable for encoder

Building instructions:

-

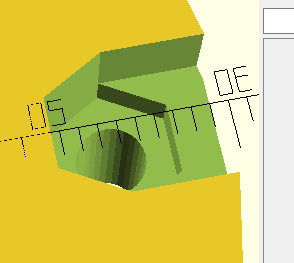

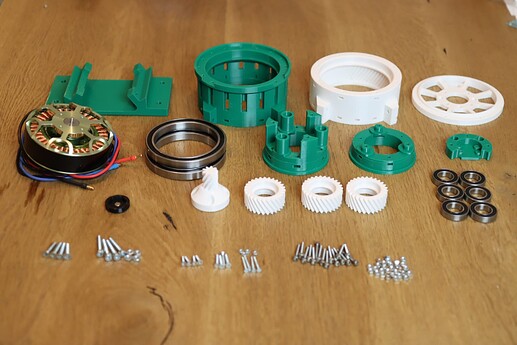

find the 3D print parts here and print them out. For orientation see picture above. Make sure the planet gears have the chamfer oriented to the bottom of the bed.

-

if needed you can find the step files here

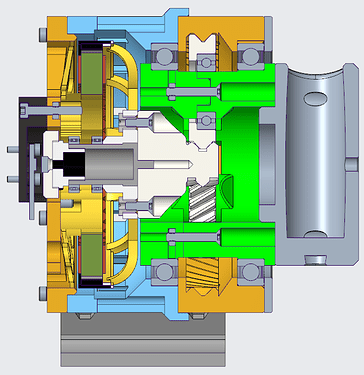

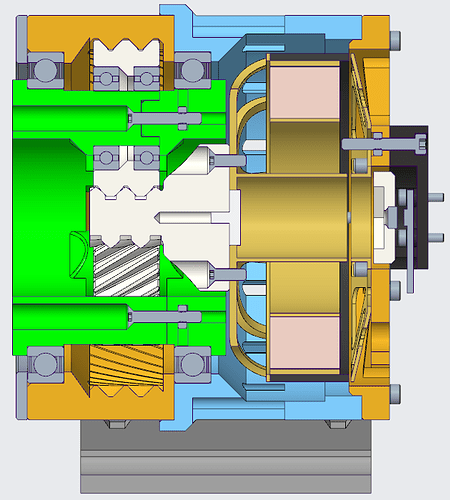

perhaps this section view will also help during the build:

First print the parts. See the picture above for the orientation on the bed. I printed everything in PET-G, with 3 perimeters, 15% gyroid infill, 4 solid bottom layers and 5 solid top layers.

You can allready mount all the M3 nuts in the little slots and hexagonal indentations. There are quite a lot of them. The large planet carrier has M4 nuts instead of M3.

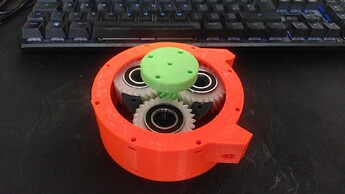

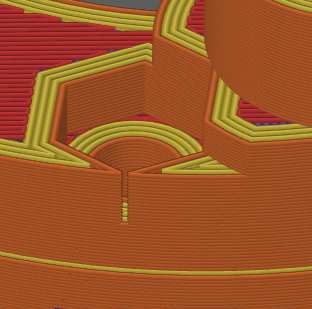

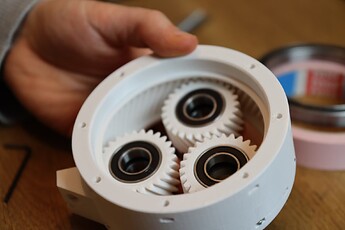

next, place the small bearings in the planet gears:

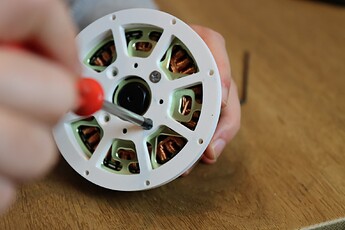

mount the sun gear on the motor using the m3 screws with flat head, length 10.

First test to see if the planet carrier fits nicely in the large bearing. I use some tape to take away any play…

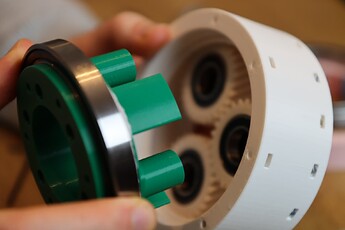

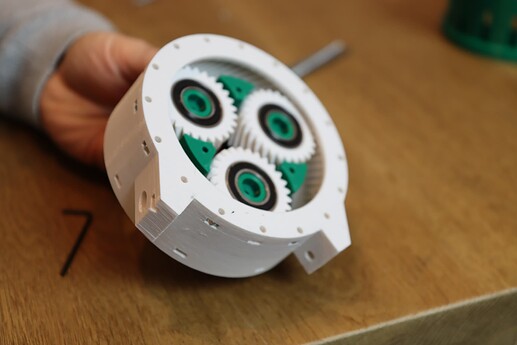

place the small spur gears in the housing with the ring gear. Try to get them in the right position. Now try and align the carrier with the 3 gears and push it in. It takes a bit of fiddling around.

Once ok, place the large bearing on the other carrier part. Again take away any play if needed.

Now install it onto the other carrier part, using 6 flat head screws M3x10 (or a bit longer)

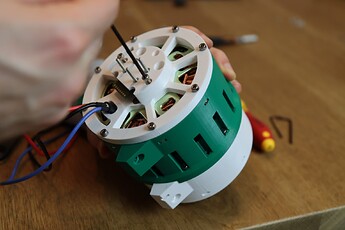

install the big housing part on the other housing part, using 8x socket M3x20

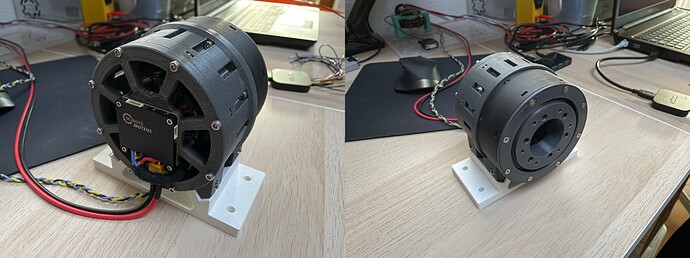

install the back plate on the motor using the flat head M4 screws length 10 or longer

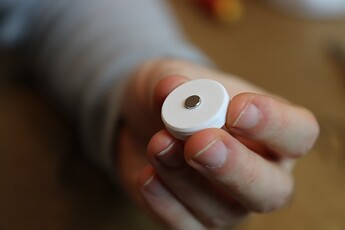

place the magnet into the magnet holder, and push it on the nut of the motor

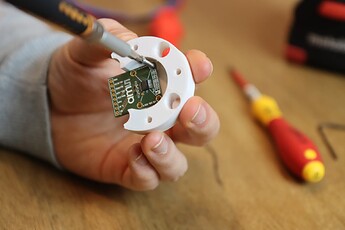

install the encoder on the encoder holder, using the M2.5 screws and nuts (note: i still need to attach a cable to it  , and the screws I have used are way too long…)

, and the screws I have used are way too long…)

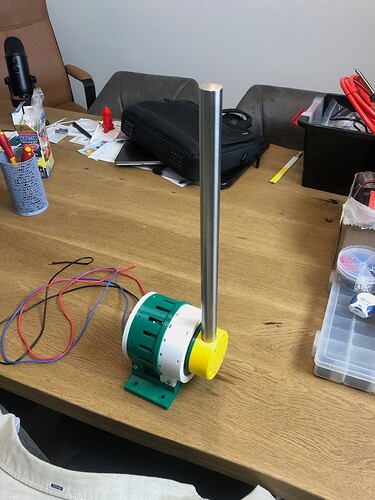

install the motor, carefully push the sun gear into the planet gears. secure back plate on the housing using m3x20 (8x)

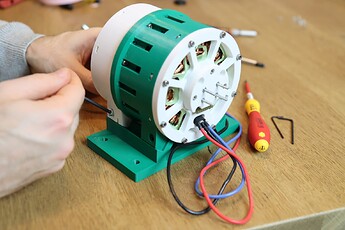

place encoder holder on back plate with socket m3 x 20

install on base plate

I have nearly finished printing one of my own.

I have nearly finished printing one of my own.